Certified Post-Consumer Recycled Plastics and Additives

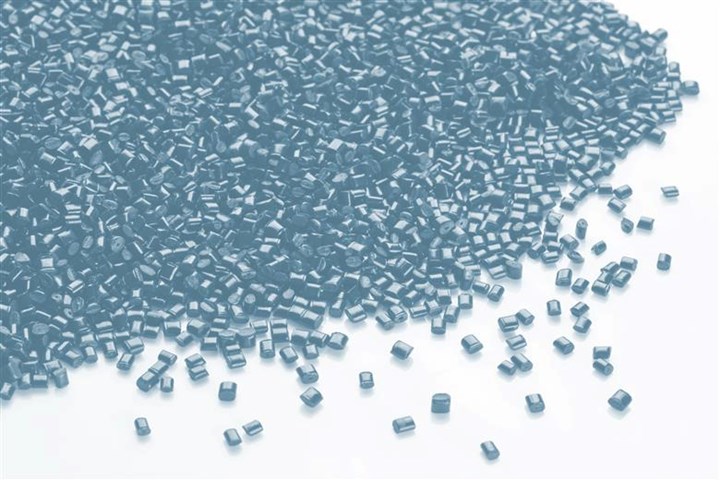

Ascend Circular Polymers’ new Cerene line include nylons 6 and 65, PP, PET and calcium carbonate derived from proprietary carpet recycling process.

, a market-leading recycler of postconsumer carpeting has launched the new Cerene a line of certified post-consumer recycled polymers and materials made from the company’s proprietary carpet reclaiming technology. Cerene is available as nylons 6 and 66, PET, PP and calcium carbonate as a consistent, sustainable feedstock for many applications, including molding and compounding.

Ascend Performance Materials, a fully integrated producer of durable high-performance materials and the majority owner of Circular Polymers by Ascend, is known for its innovations in nylon 66. Cerene will continue that legacy with offerings in nylon 66 while also bringing to market recycled polymers such as nylon 6, PET and PP. Circular Polymers by Ascend converts post-consumer carpet into fiber and pellets. The company uses a proprietary process in its California-based facilities to achieve what is said to be unparalleled efficiency in recycling, successfully providing a new life for virtually every component of the carpet and backing.

The company has redirected 85 million pounds of carpet from landfills into new goods since 2018. Ascend has a sustainability strategy based on three pillars: empowering people, innovating solutions and operating without compromise. Said Maria Field, ´óĎó´«Ă˝ director of Circular Polymers by Ascend, “Customers around the globe are seeking consistent and reliable post-consumer recycled materials. Cerene is mechanically recycled using a process that minimizes our carbon footprint and environmental impact.”

Related Content

-

Avantium and SCGC Partner to Scale-Up CO2- Based Polymers to Pilot Plant

SCGC will use Avantium’s Volta Technology which uses electrochemistry to convert CO2 to chemical building blocks such as glycolic acid which combined with lactic acid make carbon-negative PLGA.

-

Ultralight PET Preform Design

The Factor 101 design created by KHS and Husky uses just 5.89 g of material to hold 591 mL of product — equivalent to a 20-ounce water bottle.

-

Performance Nylon 6 and 66 Resins with High PCR/PIR Content

Syensqo has further extended its Omnix Echo portfolio of circular engineering resins with five new additions.