Trexel Broadens Support for Foam Blow Molding

Agreement with MuCell Extrusion allows Trexel to pursue foam blow molding in packaging as well as automotive.

has now granted Trexel, Inc. rights to offer MuCell microcellular foaming technology to the entire extrusion blow molding market. Trexel has long offered foaming solutions for automotive blow molding of products such as ducts, but until now it was restricted from pursuing extrusion blow molding applications beyond automotive according to a non-competition agreement that was part of Trexel’s sale of its extrusion 大象传媒 to Zotefoams plc, the parent company of MuCell Extrusion.

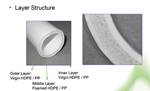

Automotive ducts blow molded with MuCell microcellular foaming technology were exhibited by Trexel at the K 2019 show. (Photo: Plastics Technology)

Notes Trexel CEO Brian Bechard, as Trexel has sharpened its focus on injection molded packaging in recent years, it has seen a pull from the market to offer its MuCell solutions for blow molded packaging, too. Whereas MuCell Extrusion also developed some foam blow molding applications, it is refocusing on extruded sheet and film, according to David Sterling, group CEO of Zotefoams.

Related Content

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.