Here's Another Process for Foam Blow Molding

After two years of behind-the-scenes development, a new process for lightweight bottles emerges into the open.

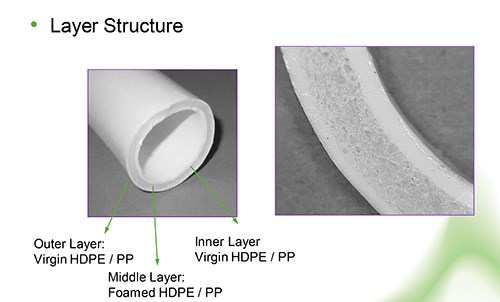

If anyone has a doubt that foam blow molding is on the verge of a renaissance, take a look at what W. Müller USA is doing. At NPE2015, the Agawam, Mass., maker of blow molding extrusion heads, spoke quietly with potential customers about a foam blow molding process that it has been working on behind the scenes since 2013. Company president Wolfgang Meyer gave Plastics Technology details on the process, which uses a special head design for three-layer coextrusion with solid inner and outer skins and a foamed center. What’s different about this process is that it uses nitrogen gas injection into the head, not into the extruder like other processes. It uses no chemical blowing agent—only talc as a nucleating agent, so it is acceptable for food packaging, Meyer says. For more details, see this month’s Starting Up section.

Other firms exploring foam blow molding include MuCell Extrusion, Trexel, and Plastic Technologies Inc.

Related Content

-

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.