SABIC’s Certified Renewable PP Used in New Coffee Capsules

Delica AG has launched the new more sustainable coffee capsule for use in it proprietary Delizio capsule machines.

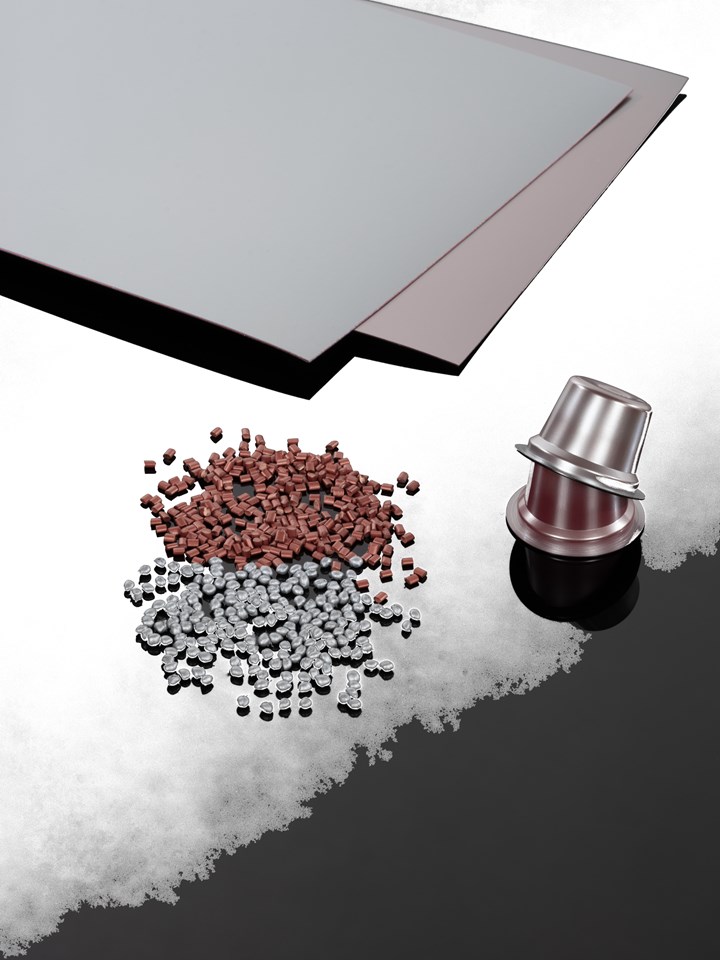

Germany’s has launched a new range of more sustainable coffee capsules for use in its proprietary Delizio capsule machines. The capsules are based on SABIC’s Trucircle certified renewable polymers, More specifically, they are produced using biobased feedstock second generation PP resins. As previously reported, SABIC’s renewable PP material, which have been shown to offer the same quality and purity as virgin PP, are produced from tall oil, an animal-free and palm oil-free waste feedstock derived from the wood pulping process in the paper industry which is not in direct competition with human food production sources.

The new capsules were introduced in the market in April 2021 and replace fossil-based virgin PP. As part of its commitment to the Delizio coffee capsule project, SABIC supplies its certified renewable SABIC PP to for conversion into a plastic film from which the capsules are thermoformed. Delica fills and closes the capsules, which are then sold to consumers through its parent company, , Switzerland's largest retail and supermarket chain.

Said Ralf van den Bragt, head of ´óĎó´«Ă˝ unit coffee at Delica AG. “A life cycle study conducted by Carbotech has shown that we can significantly reduce the environmental footprint of our Delizio capsules by replacing our former fossil-based main component with a renewable polypropylene material based on tall oil. With a certified renewable content of at least 65%, the environmental impact is reduced by approx. 40% per capsule.

Noted Philipp Broch, ALMA Packaging AG’s managing director, “Our bio PP films with SABIC’s renewable polymers provide the same convenient processing properties as conventional PP films while leading to plastic packaging solutions with high CO2 savings. They can be made with plastic based on renewable feedstock of up to 95%, as specified by the customer and certified by mass balance accounting.”

The sustainability value or contribution of SABIC's certified renewable polymers is validated using a mass balance approach under the widely recognized International Sustainability & Carbon Certification (ISCC PLUS) scheme. Mass balance is determined to allocate the renewable content used in production and conversion of the plastic material to the ultimate application. This allows brand owners like Migros to highlight and quantify the more sustainable choice consumers can make by purchasing end products packaged in renewable plastics. The ISCC PLUS accreditation verifies that the mass balance accounting follows predefined and transparent rules. In addition, the certification also provides traceability throughout the partners’ entire supply chain from the feedstock to the final product.

Moreover, a cradle-to-gate lifecycle analysis has confirmed the sustainability value or contribution of SABIC’s certified renewable materials. From sourcing the raw feedstock to producing the polymers, each ton of the company’s biobased PP and PE resin reduces CO2 emissions by an average of 4 kg as compared to fossil-based virgin alternatives, while at the same time cutting fossil depletion by up to 80%t. The study was carried out according to ISO 14040 and has been validated in a critical third-party review.

Said Abdullah Al-Otaibi, general manager of engineering thermoplastics & market solutions for petrochemicals at SABIC, “Fossil depletion and waste are among the biggest challenges on our planet and require a fundamental transformation of the value chain in the plastics economy. Our vision is that plastics should be sustainably sourced and must never end up in the environment. With our Trucircle initiative, we have positioned ourselves at the forefront of this quest and are helping converters, designers, and brand owners to collaborate and gain a sustainable edge by using high-quality recycled, circular or renewable polymer materials.”

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreNPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read MorePlastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More