Rosti North America Opens Digital Innovation Lab

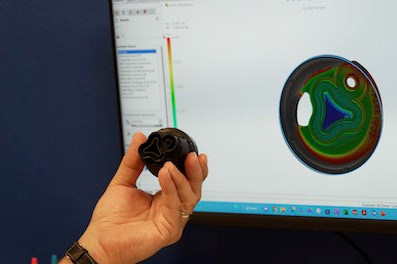

Rosti says its new lab will support injection molding and advance rapid prototyping.

Rosti North America, a division of global injection molder and contract manufacturer Rosti Group, opened a Digital Innovation Lab within the company’s Germantown, Wisconsin, manufacturing facility.

Created via an investment of $1.3 million, the latest facility joins sister labs in Asia and Europe. With this lab, Rosti says it can support 72-hour turnarounds for new concepts. Upon receipt of customers’ 3D product data and specifications, digital simulations are developed to model potential gating, cooling, distortion and cycle times.

These simulations inform the tooling process, and printed tool cavities and cores are developed using high-temperature resins. The moldings undergo optical laser scanning, providing full metrology reports within minutes, and they ready for physical testing within 72 hours. Headquartered in Malmö, Sweden, Rosti has 3,200 employees across 11 facilities in the U.S., Europe and Asia.

Rosti says its new innovation lab in Wisconsin will help it expedite the design and creation of new parts. Photo Credit: Rosti

Related Content

-

Process Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.