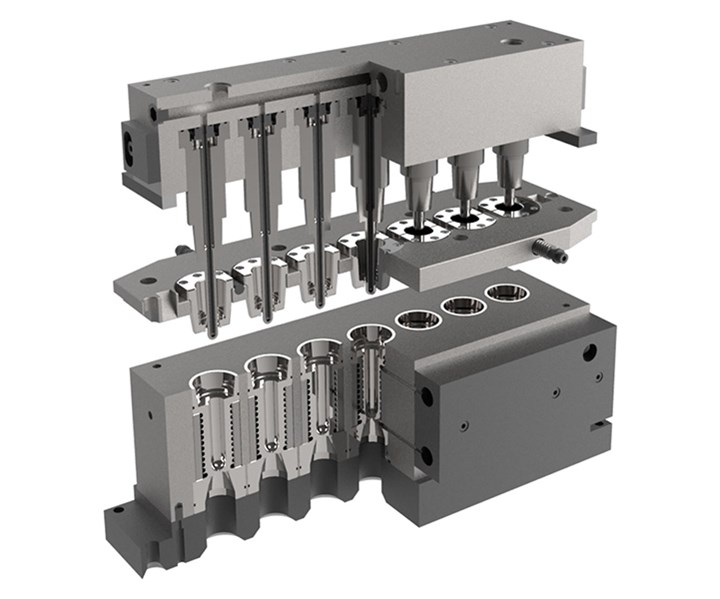

R&D/Leverage in Stretch-Blow Tooling Alliance with Aoki

A domestic source for tool design, build and repair for Aoki injection stretch-blow molding machines.

R&D/Leverage designs and builds injection-stretch-blow tooling for PET containers.

Injection and blow mold maker R&D/Leverage USA has formed an alliance with Aoki Laboratory America, whereby R&D/Leverage will be the North American designer and tool builder for Aoki’s injection stretch-blow machines. “The alliance will bring improved service for tooling, complete mods, components and/or repairs all from one domestic source,” says Mike Stiles, CEO of R&D/Leverage. The company has an Aoki lab test machine at its headquarters in Lee’s Summit, Mo.

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.