Melt Temperature Measurement Technology Enters UK Market

Melt Temperature Measurement Systems has reached an agreement with Mouldshop Ltd. to bring its measurement kit to British molders.

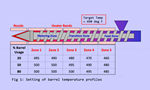

Melt Temperature Measurement System () is entering the U.K. market via an exclusive distribution agreement with Developed by Rich Bleck, MTMS enables users to measure the actual melt temperature of material in injection molding, in lieu of using barrel or set temperatures, which can be inaccurate. The kit ensures that material remains in a molten state during the reading and that the thermocouple has direct contact with the resin.

In a release, Nick Labansky, MTMS president, says the MTMS kit will be added to the Mouldshop’s website, with supporting information available directly from MTMS.

Mouldshop’s Liam Hammond says the technology would be especially beneficial to customers who must adhere to strict process conditions. In 2023, MTMS acquired the technology developed and patented by Bleck from Schmit Prototypes.

The Melt Temperature Measurement System promises users accurate readings of the actual melt temperature in injection molding. Source: MTMS

Related Content

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?