Mack Prototype Enhances CNC, Quality Inspection and Energy-Efficiency Systems

Mack Prototype’s latest technology investments coincide with its 25th anniversary.

Mack Prototype is upgrading its manufacturing capabilities with a significant investment in its machining, inspection and facility efficiencies. With a total investment exceeding $475,000, the company is revamping its CNC technology, expanding its quality lab with an advanced coordinate measuring machine (CMM) and implementing energy-efficient heating solutions.

Mack Prototype’s new Haas VF2-SS high-speed CNC mill. Source (all images): Mack Prototype

The company, a wholly-owned subsidiary of Mack Group, is augmenting its CNC machining capabilities with the addition of a Haas VF2-SS high-speed mill, which enhances the ability to machine both plastics and metals. The unit can also perform tight-tolerance secondary operations on injection-molded parts, including PPSU, PEI and composite materials.

“This investment allows us to improve accuracy, speed and quality in our machining operations,” says Greg Cebular, Mack Prototype president. “With a probing system integrated into the CNC, we can enhance precision and reduce variability in our production processes.”

Located in Gardner, Massachusetts, the company’s 75,000 square feet of manufacturing space is utilized for complex prototyping and low-volume production. Mack Prototype can take programs through the full development life cycle, drawing on 25-plus years of experience in additive manufacturing, cast urethane molding, CNC machining, injection molding and new product introduction.

The facility now houses 12 CNC 3-axis milling machines, some with 4-axis capabilities, utilizing Haas, Milltronics and Fadel CNC machining equipment.

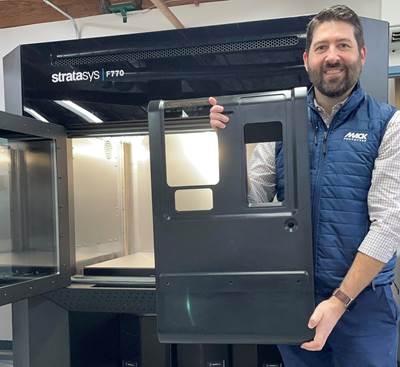

Mack Prototype President Greg Cebular poses with the company’s new Hexagon Global S7.10.7 Scan Plus coordinate measuring machine (CMM).

To complement its upgraded CNC capabilities, Mack Prototype has also invested in a Hexagon Global S7.10.7 Scan Plus coordinate measuring machine (CMM) for its quality lab. This inspection system enables the facility to measure ultratight tolerances and complex dimensions, which is critical for medical and defense applications.

“Our customers demand extreme precision, and this CMM ensures we meet those requirements,” Cebular says. “It ties directly into our CNC operations, allowing us to inspect dimensions on parts we couldn’t inspect before and significantly improve our capabilities.”

The company is also focusing on sustainability with the installation of hybrid industrial minisplit heat pumps. These systems are designed to help maximize electric efficiency while switching to backup heating only when necessary. Through partnerships with Royal Steam Heater Co. (a Gardner-based contractor) and Unitil, the company is utilizing Mass Save industrial rebates to cover a large portion of the project’s cost.

“Our goal is to reduce reliance on traditional oil and gas while ensuring a comfortable working environment,” Cebular adds. “With rebates offsetting much of the investment, we’re able to implement these energy-efficient upgrades in a cost-effective way while achieving a 25% efficiency gain over traditional heating and cooling systems.”

The company says these investments reflect its commitment to technological advancement and sustainability. By modernizing CNC and quality inspection capabilities, and embracing energy-efficient infrastructure, the company is working to deliver the best solutions for its customers.

In addition, the company has hired Robert Gilbo has to serve as quality and compliance manager. He has more than a decade of manufacturing experience in quality, operations and leadership. Most recently, he worked as quality manager at Accumet Engineering, overseeing ISO 9001 and AS9100 compliance. His background includes roles as a quality engineer at Waiteco machine and quality control technician at Keeney Holdings. Gilbo earned AS9100D Lead Auditor and AS13001/AS9117 DPRV certifications, as well as experience in quality systems, audits and continuous improvement initiatives.

Mack Prototype is a full-service prototype and low-volume production facility specializing in injection molding, urethane casting, 3D printing, CNC machining and new product introduction (NPI) assembly. The company serves a variety of industries, including medical, defense and industrial manufacturing.

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreRead Next

Mack Prototype Adds Three Additive Manufacturing Platforms

Between equipment, software and infrastructure, Mack invested approximately $750,000 in its 大象传媒 adding Carbon CLIP DLS, HP Multi Jet Fusion and Formlabs SLA machines.

Read MoreMack Prototype Expands Additive Manufacturing Capabilities

The Massachusetts-based wholly owned subsidiary of Mack Molding Co. has added a Stratasys F770 machine capable of producing large 3D-printed parts.

Read MoreThe Changing Nature of Injection Molding

As the industry enters a new year, it stands at the crossroads of global events that will change many aspects of injection molding in indelible ways—many of which are positive.

Read More