Israeli Pipe Processor Adds Potent Single-Screw Extruder

Billed as ideal for large-diam. pipes, new extruder provides processor with higher output and better quality while consuming less power.

A leading processor of large-diam. HDPE and PVC pipe added a high-performance single-screw extruder to its production earlier this year and has noticed an uptick in output and quality since.

Based in Migdal HaEmek, Israel, was founded in 1997 and ranks among the leading manufacturers of HDPE and PVC pipe in the region. The ISO 9001:2008-certified processor is well-known for its range of large-diam. pipes—up to 1200 mm for HDPE and 500 mm for PVC. In addition to its domestic market, Palad HY also Eastern and Western Europe, South America and Africa. The company’s product range includes fresh water and sewage pipe as well as pipe for natural gas distribution systems, plus protective conduits for electricity and communication lines.

Palad has been a customer of battenfeld-cincinnati since it started, and currently operates several lines from the machine builder. Earlier this year, it replaced an old extruder with battenfeld-cincinati’s solEX NG 75-40 and has been pleased with the results. “We are particularly impressed with the lower melt temperature compared to the previously used extruder, combined with better melt homogeneity and consequently better pipe quality,” says Fuad Dweik, Palad HY’s managing partner.

For Iraeli pipe processor Palad HY, the addition of a new single-screw extruder from battenfend-cincinnati has resulted in a boost in both output and quality. Pictured here are Fuad Dweik, Palad HY’s managing partner (right), with his son Rami Dweik, the firm's deputy manager.

For Iraeli pipe processor Palad HY, the addition of a new single-screw extruder from battenfend-cincinnati has resulted in a boost in both output and quality. Pictured here are Fuad Dweik, Palad HY’s managing partner (right), with his son Rami Dweik, the firm's deputy manager.Lower melt temperatures have also helped the processor produce pipe with more even wall-thickness distributions within extremely narrow tolerances, with less undesirable sagging. Naturally, better pipe quality also reduces material consumption and cuts down on scrap. “Both the material savings and the roughly 10% reduction in energy consumption due to the lower heating rates make this extruder a particularly cost-efficient alternative,” adds Dwiek, who said his company is already thinking about a further investment in another solEX NG extruder.

“Both the material savings and the roughly 10% reduction in energy consumption due to the lower heating rates make this extruder a particularly cost-efficient alternative.”

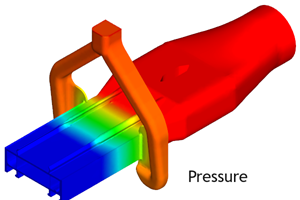

The completely redesigned processing unit on the new extruder series accounts for these improvements, says battenfeld-cincinnati. Internally grooved barrel combined with a matching screw and grooved bushing geometry reportedly offers substantial improvements in process technology. A reduced axial pressure profile lessens machine wear. High specific output rates with lower screw speeds ensure high efficiency, and the gentle but highly effective and homogeneous melting performance at about 10 °C lower melt temperatures compared to conventional processing units.

The extruder is equipped with the BCtouch UX control system, which, in addition to modern functionalities, also includes the possibility of individualization or personalized user interfaces. “For our staff, it is a great benefit that the equipment can now even be operated in Hebrew, and that the battenfeld-cincinnati service team is available 24/7,” notes Rami Dweik, son of the proprietor and responsible for production in his role as deputy manager.

The solEX NG extruders series is available with screw diam. of 60, 75, 90 and 120 mm in a throughput range from 1653 to 5511 lb/hr.

Related Content

Updated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read MoreCrosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreHigh-Output Extruder Series Now Comes in Smaller Size

Series offers higher output, lower melt temperatures and energy savings.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More