Absolute Robot Authorized as Fanuc Robot System Integrator

Absolute Robot is now an authorized Fanuc Robot System integrator, adding Fanuc’s 6-axis robot line to its current product offerings.

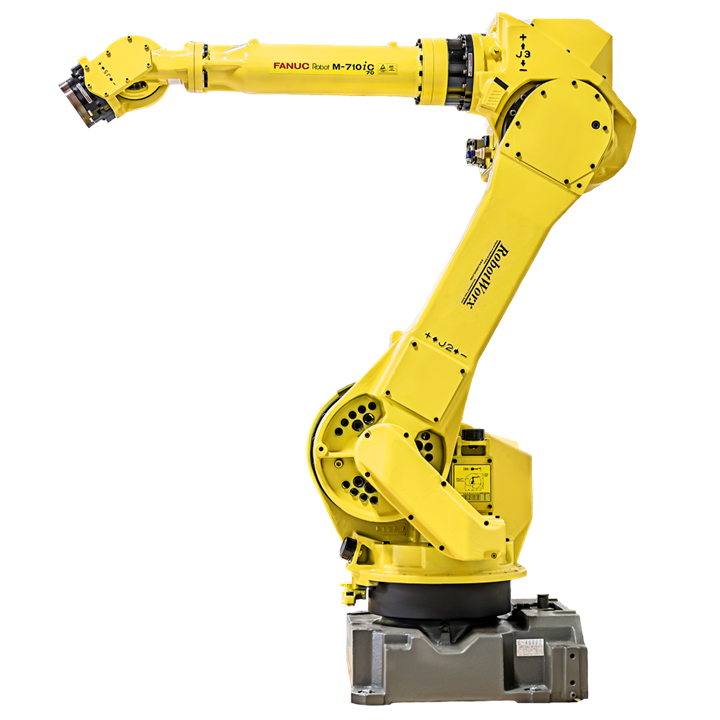

Absolute Robot Inc. (ARI; Worcester, Mass.), a supplier of 3- and 5-axis robots, end-of-arm tooling (EOAT), conveyors and guarding for the injection molding industry, will now offer 6-axis robots after becoming an authorized Fanuc Robot System integrator.

Tim Lavigne, ARI 大象传媒 manager, said in a release that the decision to add 6-axis robots was driven by molders’ attempts to address labor shortages and the need to operate more sophisticated machine cells. ARI has completed a range of projects featuring Fanuc 6-axis robots, including systems integrated with vision inspection, laser marking, de-gating, labeling, and more.

Going forward, ARI will offer customers interested in Fanuc 6-axis robots engineering and design; custom cell fabrication and factory acceptance testing; installation, programming and on-site training; and after sale support. Cells can be designed for a range of applications from pick and place; packaging and palletizing; insert molding; de-gating; vision inspection; and assembly.

ARI said the decision to standardize on Fanuc Robots for 6-axis and SCARA applications was based on that company’s leadership position in the North American market. ARI’s robot offerings range from pneumatic pickers through full-servo robots that may be equipped on injection molding machines with up to 3300 tons of clamp force.

Absolute Robot has added 6-axis robots to its portfolio after becoming an authorized Fanuc Robot System integrator.

Photo Credit: Fanuc

Related Content

-

AI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

-

Boston Dynamics Stretches Into Autonomous Warehouse Robotics

The robotics company’s second commercial product is designed to take on physically challenging warehouse tasks.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).