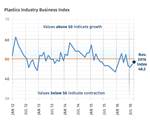

December’s Index—49.4

The overall processing market is growing, though custom processors had a slower fourth quarter.

At 49.4, Gardner’s Plastics Business Index revealed that the industry contracted for the second month in a row in December, albeit at a slower rate than in November. In general, the industry has trended up since July.

Plastics/rubber processors have experienced strong growth in four of the last five months. However, custom processors contracted at an accelerating rate for the third month in a row. Among major end markets, automotive grew strongly for the second month in a row. The electronics index increased for the third time in four months. But the medical index remained weak.

New orders and production contracted for the second month in a row. The backlog index, while continuing to contract, jumped significantly in December. The index reached its highest level since January 2015, which was the last time backlogs increased. Employment contracted after two months of growth. The export index was just below 50 for the third straight month. Supplier deliveries continued to lengthen but at the slowest rate since August.

Material prices increased at an accelerating rate in December. The index was at its highest level since October 2014. Prices received increased for the third time in four months. The rate of increase was the fastest since October 2014. After a huge jump in November due to the election results, the future ´óÏó´«Ã½ expectations index was unchanged in December.

The Southeast was the fastest growing region for the second consecutive month. It has grown for the last eight months. The Northeast has grown in three of the last four months.

Processing plants with more than 250 employees contracted for the third time in four months. Facilities with 100-249 employees were flat after four months of growth. Companies with 50-99 employees contracted for the second month. Processors with 20-49 employees contracted for the first time since August. Processors with fewer than 20 employees expanded for the first time since January 2015.

ABOUT THE AUTHOR: Steven Kline Jr. is part of the fourth-generation ownership team of Cincinnati-based Gardner Business Media, which is the publisher of Plastics Technology. He is currently the company’s director of market intelligence. Contact: (513) 527-8800;

email: skline2@gardnerweb.com

Gardner Economics Blog

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

.JPG;width=70;height=70;mode=crop)