Want to Get More Out of Your Hydraulic Machines?

Get up to 10% more energy efficiency out of a hydraulic press without spending a penny on drive hardware upgrades.

Get up to 10% more energy efficiency out of a hydraulic press without spending a penny on drive hardware upgrades.

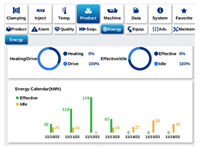

Injection molders today have a daunting range of choices when shopping for the most efficient machine—all-electric, partially electric (hybrid), hydraulic with electric servo or variable-frequency (VFD) pump drive, or plain old-fashioned fully hydraulic. But what if you heard that you could get up to 10% more energy efficiency out of a hydraulic press without spending a penny on drive hardware upgrades?

At last October’s K 2016 show in Dusseldorf, the German chemical company Evonik (U.S. office in Parsippany, N.J.) revealed the results of tests in 2015 on its Dynavis oil-additive technology in a Boy 35-ton and an Engel 120-ton press. Comparisons with standard hydraulic oild showed energy savings of 6% to 10%. Details of the tests are available at .

Normally, hydraulic equipment works at optimal efficiency when the oil is within a particular temperature range. Oils formulated with Dynavis technology (which utilizes Evonik’s Viscoplex family of polymer-based viscosity improvers) extend that high-efficiency temperature range.

The modified oils both flow better at low temperatures and remain more viscous at higher temperatures. When such oils are used in injection molding machines, the press reportedly uses less drive energy, and the oil does not get as hot and withstands shearing forces better. Until recently, Dynavis technology has been used mainly in construction equipment. Dynavis technology has been licensed to a number of hydraulic-oil suppliers around the world.

Related Content

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.