Tiny Part Showcases Big Molding, Moldmaking Capabilities

Grab a magnifying glass and check out this entrant in Molding 2021’s Hot Shots injection molded part competition.

Matrix Tool (Fairview, Penn.) figured the best way for it to showcase its advanced moldmaking capabilities and the unique abilities of its Sodick Plustech injection molding machines was to create a showcase part and mold.

That part is just one of the entrants in the inaugural Hot Shots injection molded part competition, which will take place during the later this month in Chicago (Sept. 21-23; Donald E. Stephens Convention Center; Rosemont, Ill.).

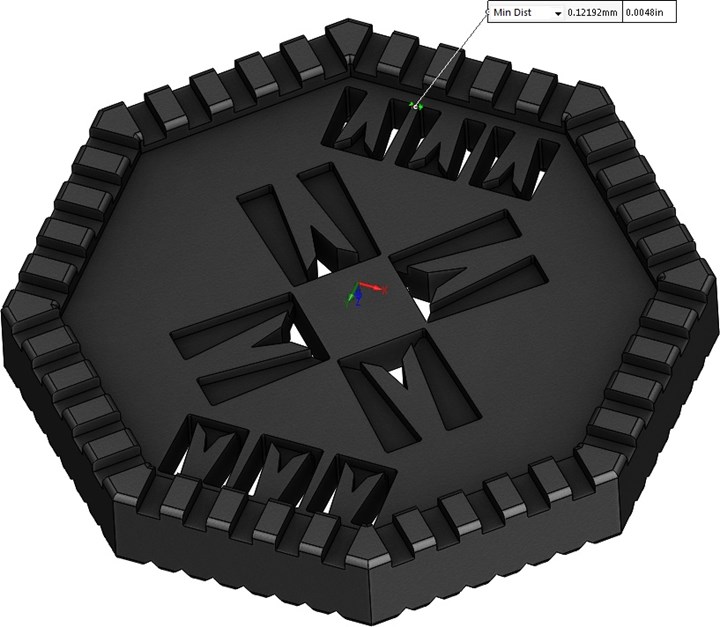

Molded from Sumitomo’s Sumika Super LCP resin on a two-stage Hi-Response injection molding machine from Sodick, the showcase part has a wall thickness of just .0048 inch, and is filled in 0.16 second.

Matrix designed this tiny LCP parts with intricate geometry to showcase the advantages of small tools and fast clamping, which it says can out produce larger machines running high cavity tools. Listen in to my conversation with Tom Moyak and his team at Matrix, as well as Len Hampton of Sodick, to learn more about this Hot Shots entrant, and register today for to see all the parts in person in Chicago.

Matrix Tool and Sodick Plustech have entered this unique LCP part with micro features into Molding 2021’s Hot Shots part competition.

Related Content

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

Process Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.