Life Cycle Assessment of PVC Water and Sewer Pipe

Comprehensive study compares health, safety, performance and sustainability attributes of different pipe materials.

A comprehensive environmental and performance review of water and sewer pipes in North America was recently commisioned by Dallas-based Uni-Bell PVC Pipe Assn. (PVCPA), which represents U.S. and Canadian manufacturers of PVC pipe.

The PVCPA hired sustainability consulting firm, Sustainable Solutions Corp. (SSC), to conduct the review, which is entitled The Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials.

SSC engineers used the ISO 14040 series life cycle assessment (LCA) standards to evaluate PVC pipe’s environmental footprint. The peer-reviewed report also examines other pipe products based on durability, performance and environmental data and statistic when available.

Said SSC president Tad Radzinski:

“The PVC pipe industry is the only pipe material that has transparently reported its sustainability and environmental impacts…this is welcome information for both policy makers and utility professionals to make fully informed decisions in their efforts to improve underground infrastructure with sustainable products.”

Added PVCPA’s executive director Bruce Hollands:

“This study provides critical information for federal, state and local policy makers as they look to modern piping materials to help rebuild the nation’s crumbling underground infrastructure…it confirms that safer, more cost-effective and more durable PVC pipe is key to upgrading America’s drinking water and wastewater systems.”

Here are some of the study’s key findings:

- When evaluating the sustainability of piping products for life cycle design, it’s important to understand and review the life cycle impacts of all materials used in the piping system, including replacements, support materials, corrosion migration, maintenance efforts and water quality treatments required during the service life of pipes.

- Based on over 60 years of field experience, dig ups, laboratory testing, and given its immunity to corrosion and low break rate, a service life in excess of 100 years was confirmed for PVC pipe.

- PVC does not serve as a nutrient for bacterial growth and pathogens.

- Keeping pipes in use past their useful service lives results in higher operating and maintenance costs. Internal pipe wall degradation may begin almost immediately after ductile iron and concrete pipes are installed.

- Traditional definitions of pipe service life should be re-evaluated. For much of the time that iron and concrete pipes are considered “in service”, they in fact are not, since they often do not perform as designed. For a good portion of the time they are in use, iron and concrete pipes are prone to breaks, water loss and water quality issues, as well as higher maintenance and operating costs due to corrosion, which significantly affects pumping efficiency.

- PVC pipe is a low initial cost option and provides long-term savings because of its superior pumping efficiency, corrosion resistance and longevity.

- Metallic and concrete pipes required chemical additives (phosphates) in the drinking water to help reduce pipe wall corrosion. Phosphates increase the chances of bio-growth—such as algae blooms—in drinking water sources, lakes and rivers.

- Ductile iron pipe produces up to nine times more carbon emissions during raw materials processing, manufacturing, transportation and installation than equivalent PVC pipe.

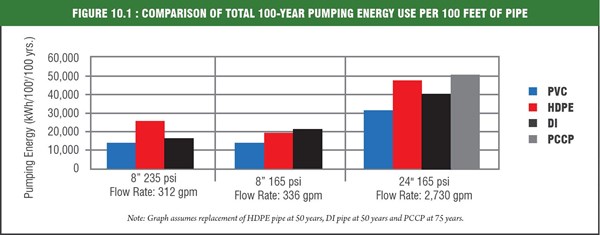

- 66% of water supply pipes in the U.S. are 8-inches or smaller. Nationally, using PVC instead of ductile iron pipe in this size range could save $21 billion in pumping costs over 100 years. If PVC were used instead of HDPE pipe, $37 billion could be saved.

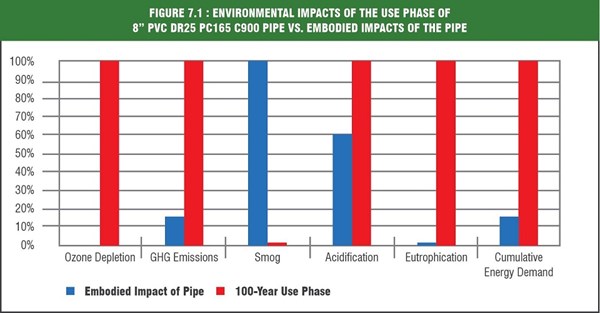

- Water and wastewater utilities often represent as much as 40% of a municipality’s total energy consumption. The energy required to pump water through a pressurized pipe system over the life of the pipe is a significant source of potential environmental impacts.

- The energy required to pump water through PVC pipe over a 100-year design life remains constant because its smooth walls do not roughen over time. This generates overall life cycle cost savings compared to ductile iron and concrete pipes that require more pumping energy over time due to corrosion, leaks and internal degradation.

- Corrosive soils affect 75% of water utilities. The durability and corrosion resistance of a pipe greatly affects life cycle impacts. Ductile iron pipe may last as little as 11-14 years in moderately corrosive soils, requiring numerous replacements over 100 years.

- For equivalent 8-inch pipes, it takes up to 54% more energy to pump water through ductile iron pipes than through PVC pipes, and 100% more energy to pump water through HDPE pipes than PVC pipes.

- Of the competing pipe materials, including iron, concrete and HDPE, PVC is the most favorable alternative when considering the product’s energy consumption and carbon footprint from cradle-to-grave in a public water system.

- Recycled material is only a single attribute of a pipe’s life cycle environmental impacts. For example, more energy is required to process the recycled metals to manufacture ductile iron pipe than in PVC pipe production. As well, producing iron pipe with recycled scrap iron emits more toxins than pipe made from virgin iron ore.

Related Content

LyondellBasell Showcasing End-Use Applications in 5 Key Markets

NPE2024: LYB is highlighting applications in circularity, mobility and transportation, food and medical, consumer goods/lifestyle, and infrastructure/building and construction.

Read MoreIPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

Read MoreEV Chargers Made From Renewable PC

SABIC is enabling Charge Amps to manufacture electric vehicle (EV) chargers with a housing made from certified renewable PC, a first for the industry.

Read MoreIneos Nitriles Launches Biobased Acrylonitrile

The company’s Invireo is said to deliver a 90% lower carbon footprint compared to conventionally produced acrylonitrile.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More