Breakthrough Opens Up Landscape for Biobased Materials

DuPont and ADM have “game-changing” platform technology based on long sought-after molecule.

DuPont and ADM have “game-changing” platform technology based on long sought-after molecule.

With a Dupont-Dow Chemical merger in the wings, any industry observer can say sustainable materials have been a key focus of each company in recent years—be they engineering thermoplastics with biobased content or innovative packaging breakthroughs (e.g., stand-up pouches) with structures that promote recyclability. So, while this mega-merger is pending, new developments continue to emerge.

The newest one is the announcement of a new “breakthrough process” jointly developed by and (ADM) reportedly enables the production of furan dicarboxylic methyl ester (FDME) from fructose. A high-purity derivative of furandicarboxylic acid (FDCA), FDME is one of the 12 building blocks identified by the U.S. Dept. of Energy that can be converted into a number of high-value, biobased chemicals or materials that can deliver high performance in a number of applications.

The partners see this molecule as a “game-changing” platform technology that has the potential to expand the materials landscape in the 21st century with truly novel, high-performance renewable materials with applications in packaging, engineering plastics, textiles and other industries. This collaborative effort brings together ADM’s expertise in fructose production and carbohydrate chemistry with DuPont’s biotechnology, chemistry, materials and applications expertise—all backed by a strong joint intellectual-property portfolio.

“This technology will enable cost-efficient production of a variety of 100% renewable, high-performance chemicals and polymers with applications across a broad range of industries. ADM is an agri´óĎó´«Ă˝ powerhouse with strong development capabilities. They are the ideal partner with which to develop this new, renewable supply chain for FDME,” said Simon Herriott, DuPont’s global ´óĎó´«Ă˝ director for biomaterials.

One of the first material under development utilizing FDME is polytrimethylene furandicarboxylate (PTF), touted as a novel polyester also made from DuPont’s proprietary Bio-PDP (1.3-propanediol). A 100% renewable and recyclable polymer, PTF is said to substantially improve gas-barrier properties over other polyesters in bottles and other beverage packages. So, PTF will be positioned as a challenger in applications where the beverage packaging industry is aiming to improve shelf life and lighten the weight of their products.

The partners are taking the initial step in the process of bringing FDME to market by moving forward on the scale-up of the project. Plans are for an integrated 120,000 lb/yr demonstration plant in Decatur, Ill., which will provide potential customers with sufficient product quantities for testing and research.

Among the key advantages cited for the new approach to producing FDME are:

• Higher Yields and Lower Operating Costs: This process is said to deliver the possibility of commercially available FDME. Compared to the current process, which also makes other byproducts, this innovative process uses all sugar in the feedstock—either to make FDME or for energy recovery.

• Better Performance: The process is said to result in increased performance for all the products that will use FDME as a building block, including high-performance renewable chemicals and polymers (polyesters, nylon, plasticizers, and polyurethanes) with applications in industries such as packaging, engineering thermoplastics, and textiles.

• Smarter Renewable Materials: Not only can this process reportedly replace petroleum-based materials in a wide variety of applications, but the process of making FDME is ‘smarter’. Additionally, with all the process steps co-located in one facility, all operations are more energy efficient.

Related Content

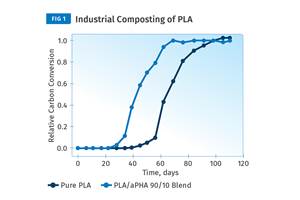

Blend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

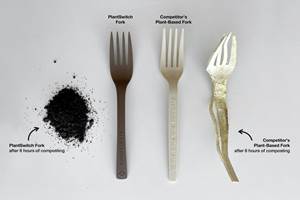

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreResearch Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More