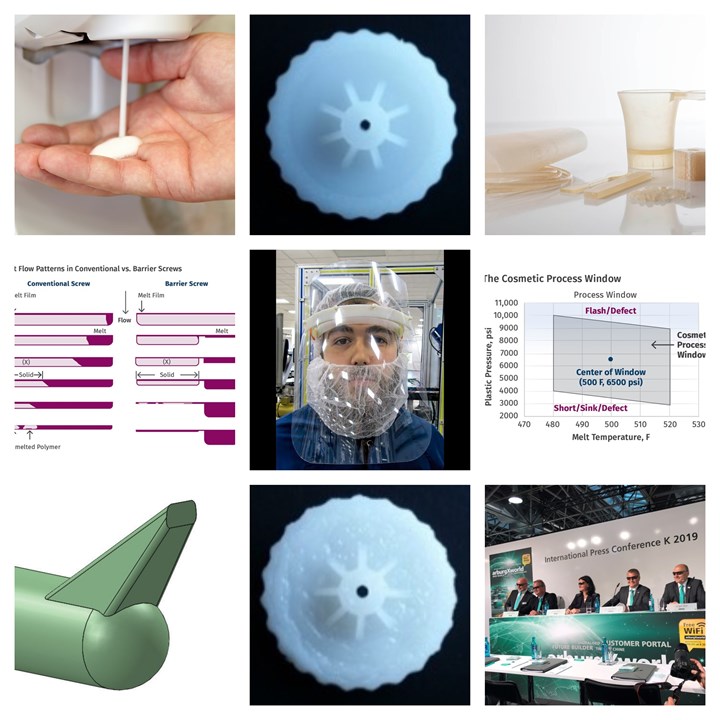

April's Most Popular Stories: Covid-19, Cosmetic Process Windows, Compounding, Plastic Wars and More

Processing tips from widening injection’s cosmetic window to sizing gates, runners and sprues in tooling and understanding devolatilization in extrusion garnered reader interest in April, as did the plastics industry’s collective reaction to Covid-19.

Know How columns for injection molding, tooling and extrusion all generated reader interest in April, as did a Tips article looking at devolatization in compounding and a new renewable material. Elsewhere, PT’s coverage of industry suppliers and processors stepping up to assist in the national effort against the coronavirus captured site visitor attention.

- The Cosmetic Process Window: Key to a No-Tweak, Robust Process

- Surging Demand for Hand-Sanitizer Dispensers Keeps Molding Machines Busy

- Extrusion: Important Polymer Melting Equations for Extrusion Processors

- Tooling: How to Properly Size, Gates, Runners and Sprues, Part 2

- Plastic-Like Packaging Material Made from Completely Renewable Raw Materials

- Tessy Plastics Initiates Face Shield Manufacturing to Help Combat Covid-19

- Covid-19 Pushes Manufacturers into Emergency Ventilator Component Supply

- Compounding: Part 2 of 2 Demystifying Devolatilization

- Tradeshow Giveaway Converted to Personal Protective Equipment (PPE)

- Why ‘Plastic Wars’ Got Me Riled

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.