Matthew Naitove Contributing Editor

Powder Injection Molding Helps PTI Thrive in Specialties

“We like challenges. We like to do things that other people are scared to do.”

Read MoreUV Cure Solves LSR Processing Challenges

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology.

Read MoreAuxiliaries at NPE: New Solutions from Material Preparation To Post-Mold Operations

There will be an extraordinary range of new auxiliary equipment on display at the show.

Read MoreTooling at NPE: A Hot-Runner Bonanza in Orlando

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read MoreNow You Can Measure Pellet Moisture In the Hopper, in Real Time

Take the guesswork out of drying with new technology.

Read MoreTightening the Screws on Precision Molding Of Thermoplastics & LSR

Fairly consistent focus of annual conference was how to get better control of the molding process.

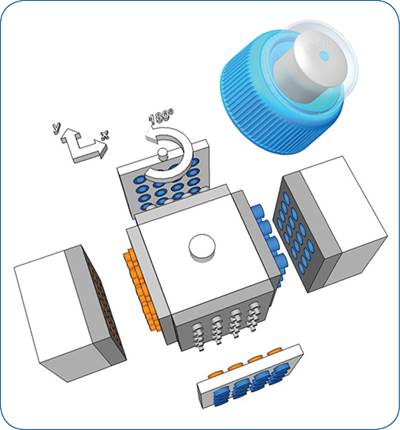

Read MoreMaking Older Hydraulic Injection Machines More Energy Efficient

Processor Strategies: Motor Controllers

Read More'Global' Ultrasonic Power Supplies Boast 'World First' Innovations

Branson Ultrasonics Corp., Danbury, Conn., has just introduced its first “global” series of ultrasonic welding power supplies for automated assembly systems, which are said to incorporate several “first-in-the-world” capabilities.

Read MoreOn-Site: Custom Molder Pursues the Dream of Proprietary Products

“Every custom molder thinks he needs a proprietary product,” says John Currier, president and co-owner of the injection molding firm his father founded, Currier Plastics in upstate Auburn, N.Y.

Read MoreModular Conveyor Boosts Productivity and Profits for Toothbrush Manufacturer

Automation in plastics processing can involve sophisticated, high-tech manufacturing cells specialized for a particular application (see NPE feature this month ). Or it can involve much simpler, off-the-shelf solutions that offer the user flexibility to configure—and reconfigure—an automation system according to the job and plant layout.

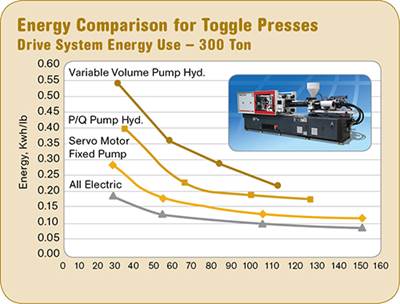

Read MoreMore Hydraulic Presses Get Energy-Saving Servo Drives

Injection molders who want to save energy costs have a growing number of alternatives.

Read More