.jpg;maxWidth=250;quality=70)

John Bozzelli Founder

Follow These Tips to Sanitize Machine Controller Screens & Buttons

Keeping your workers safe from the coronavirus makes it extremely important to institute a sanitizing procedure on all touch surfaces of the controller, screen and operating panel. I did some research and here’s what I found.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

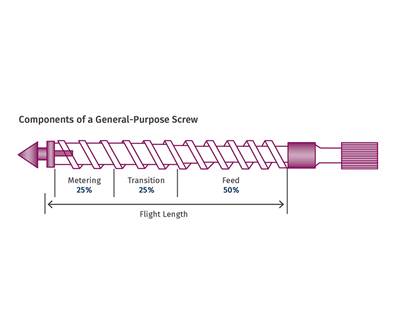

Read MoreRevisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

Read MoreChecking and Controlling Nozzle Body Temperature

Temperature control is critical from feedthroat to nozzle tip. Yet despite advances in machinery, this continues to be an issue for molders. Here’s what to do about it.

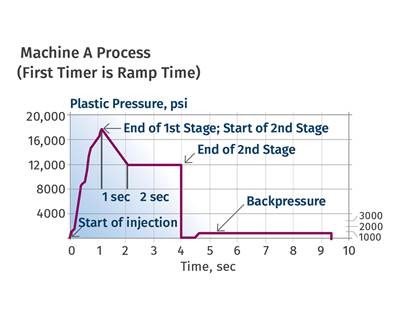

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreHow to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

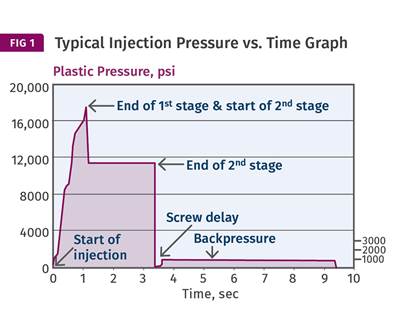

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

Read MoreMold-Clamping Details for Profit

Taking time to sweat the details of clamping is not much fun, but they do make a difference in a company’s bottom line.

Read MoreWhat’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

Read MorePART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

Read MoreInjection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

Read More