What Is a Second Worth?

When you are buying a molding machine, the author advises, you should balance the initial price against the payback in productivity.

Every molder knows that time is money, but identifying the value of a single second’s worth of cycle time might seem like splitting hairs. Yet a second saved on every cycle adds up to hours of valuable machine time and reduced part costs. Calculating the value of a second in a molding operation can give a new perspective on capital investment choices, a key factor in overall cost reduction.

Molding machines and other capital equipment represent a fairly small share of the manufacturing costs for most plastic parts. Resin represents the largest chunk of the total—by some estimates, up to 75% of part cost. Among the cost factors that the molder can control, labor and overhead costs can provide ample opportunities for cost reduction on a plant-wide basis.

Although the molding machine and related equipment typically represent only about 12% of the overall cost of producing a part, this cost component can be affected by wise buying decisions. Thus, equipment takes on greater importance than its share of the cost equation might suggest.

Wise capital-investment decisions rarely depend solely on the initial price of the machine. Instead, they are based on the total cost of operating the equipment—including labor, utilities, and cycle time. While all these factors are important, cycle time looms largest. A premium purchase price based on cycle-time savings alone can often be justified in two years or less.

Pricing a second

There are several ways of calculating a second’s value. For most molders, especially custom molders, value is best viewed through the lens of machine-hour rates. First, figure out the total number of production hours available in a year. For example, a shop that runs around the clock, seven days a week for 50 weeks per year would have a maximum of 8400 hr available. Assuming an uptime efficiency of 95%, 8000 hr/yr are available for molding.

Next, figure out the hours saved from a one-second reduction in cycle time and multiply that figure by the machine-hour rate. For example, if the molding cycle on a given part is reduced from 10 to 9 sec, that 10% reduction adds up to savings of 800 hr/yr in an 8000-hr/yr shop. For a press in the 300-499 ton range, with a typical machine-hour rate of $48.50, the additional 800 hr made available by a 1-sec shorter cycle is worth $38,800 in machine-hour cost. Of course, to realize this benefit we assume that the additional production time can be sold or used for another molding project.

Another method of calculating the value of a second is to look at the incremental revenue it generates. Using the same cycle-time reduction of 10 to 9 sec for a 32-cavity mold, we can calculate the additional output per year. The 800 hr gained represents another 320,000 cycles. The additional output for the 32-cavity mold would be 10 million parts. If the selling price was $15/1000 parts, the incremental revenue would be $150,000/yr. Again, to realize the benefit, the molder must be able to sell the additional output. A very similar calculation would be performed based on profit. For the same 32-cavity example, using a profit of $2/1000 parts, the additional 10 million parts would generate $20,000/yr.

Investment choices

Once we know the value of a second in the molding operation, we can ask ourselves what we are willing to invest to gain a second.

To see how a second’s value can affect machine choices, consider this comparison:

- Machine A of 500 tons costs $200,000, carries a machine-hour rate of $48.50, and can produce a part in a 10-sec cycle.

- Machine B of 550 tons costs $250,000, has a machine-hour rate of $50.40, and can produce the same part in 9 sec.

As shown in the table, faster Machine B generates as many cycles in 8000 hours’ running time as Machine A would if it ran for 8900 hr. That would provide $43,000/yr of additional saleable machine time at Machine A’s hourly rate. Thus, Machine B’s $50,000 higher initial cost is offset by a 14-month payback based on cycle time alone.

Now consider a scenario in which the cycle time for Machine A is 60 sec compared with 59 sec for Machine B. The table shows that a cycle-time saving of 1 sec would yield the equivalent of only 136 hr extra running time for Machine A, worth just $6600/yr. The resulting 8-yr payback time would probably not justify the higher price of Machine B, given the shortness of typical product lives today.

Cycle time isn’t the only way to justify a machine purchase. Energy efficiency, labor requirements, uptime, and scrap rate all help determine a machine’s true cost. For example, the higher injection speed of an accumulator-based machine can reduce part weight and warpage. Also, warranty coverage can reduce maintenance costs over the life of the machine. Machines with a longer service life also have a more favorable depreciation.

Even though cycle time isn’t the only way to identify the true value of a machine, it gives the the quickest snapshot of value and tells when a more expensive machine is worth a second look.

Related Content

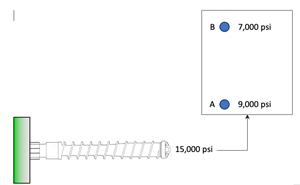

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreProcess Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More