How United Plastics Became A Quick-Change Artist

United Plastics Corp., a small profile and sheet extruder with 125 employees in Mount Airy, N.C., combines an almost unbelievably diverse product mix (it has some 5000 dies in active use) with the ability to change over individual extrusion lines four or five times a day.

United Plastics Corp., a small profile and sheet extruder with 125 employees in Mount Airy, N.C., combines an almost unbelievably diverse product mix (it has some 5000 dies in active use) with the ability to change over individual extrusion lines four or five times a day. The company also has vertically integrated raw-material blending and compounding to fill its long menu of short-order recipes.

United’s 24 Davis-Standard extrusion lines include five for flexible sheet (20- to 96-in. wide), a dozen for rigid PVC profiles, and seven for flexible PVC profiles. Eighty-five percent of its production is vinyl; the rest is PP, TPO, styrenics, and EVA. It pulverizes, blends, colors, reclaims, and compounds its own raw materials.

United spent most of its 58 years belonging to a series of giant global manufacturers. It was founded in 1946 as Carolina Industrial Plastics and originally extruded vinyl clotheslines. It was acquired in 1952 by Essex Wire & Cable, which converted it to extrusion of black vinyl tape for wire wrap.

In 1972 Essex was bought out by United Technologies Corp., and the Mount Airy plant became part of UT’s Automotive Group. It expanded into flexible PVC gaskets and seals for cars. By 1992, UT Automotive was sold and split up. The Mount Airy plant was bought by an investment group in Detroit, which sold it two years later to United Plastics managers and a group of Mount Airy investors.

When the hometown team took over, 65% of United Plastics’ sales were in automotive. Eight years later, the company has trimmed its dependence on automotive to only 35% to 40% of sales. Products that have grown to replace the automotive ´óĎó´«Ă˝ include foamed and woodgrain-pigmented PVC “lumber” profiles, TPO sheet for roofing, and EVA sheet for sound deadening. Its product slate of small profiles also includes rigid PVC door and window parts, two- and three-layer coextrusions, living hinges, and flexible PVC gaskets and trim. Most of the dies would fit in the palm of your hand, and all 5000 of them fit into small wooden cubbies lining two walls of the plant’s die shop.

Five changes a day

United cuts almost all its dies in-house and has four full-time CAD engineers to design them. The dies are especially short because that makes them easy to change. United may run a profile for only 3 to 4 hours, whereas most custom profile extruders want jobs that run for days or weeks. An extruder at United Plastics may change dies four or five times in 24 hr. Explains Kenneth Roush, United’s president, “Our short dies would burn profiles on longer runs, but they’re easy to set up for short runs.” Changing a non-calibrated flexible PVC line takes about 20 min; a calibrated rigid profile line may take 90 min.

Quick changes have paid off. “While other processors’ ´óĎó´«Ă˝ has been shrinking, we’ve been growing,” says Roush. United runs all its lines around the clock, seven days a week for sheet and a five days a week for profiles.

Recycling joins the mix

Perhaps as atypical as the extraordinary number of products it makes is United’s vertical integration in raw materials. The company does its own short-order dry blending and color mixing. “We make over 300 approved colors for the automotive industry,” Roush notes.

Last January, United added recycling to its raw-material arsenal, so it now reclaims PVC carpet backing to create new compounds. United’s 12,000-sq-ft reclaim plant includes a large Vecoplan ReTech shredder, a Cumberland granulator, and three elutriators (air separators) from Sterling Elutriation in Forest, Va. The carpet scrap is shredded, pulverized, and then sent through all three elutriators in succession. The elutriators separate the calcium carbonate-filled flexible PVC backing from the lower-density carpet face fibers at up to 2000 lb/hr. Face fibers are compacted and shipped out for waste-to-energy incineration.

Reclaimed PVC crumb is extruded into black PVC sheet that is used as an underlayer in new carpeting. “Our skills as reclaimers and compounders let us compete against much bigger companies,” says Roush. “We stay ahead by innovation and diversity.”

Related Content

High-Output Extruder Series Now Comes in Smaller Size

Series offers higher output, lower melt temperatures and energy savings.

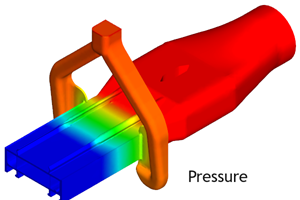

Read MoreUpdated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read MoreExtrusion Excellence: This Year's Top Stories

Revisit the year’s most popular articles on extrusion technology and processes, showcasing innovations, best practices, and the trends that captured the plastics processing community’s attention.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More