Some (Don’t) Like It Hot: Overcoming Thermochromism Challenges in Plastics Manufacturing

A new means of effectively testing thermochromism’s impact on color in plastics enables accurate measurements without time-consuming cooling.

Temperature variations can cause temporary color changes in plastics and other materials. This phenomenon, known as thermochromism, is the principle behind novelty items like mood rings and color-changing mugs, as well as heat-measuring products such as forehead thermometers and baby bottles. In plastics manufacturing, however, this effect can lead to inaccurate color measurements if a sample’s temperature differs from its reference standard. Even small variations can be problematic, particularly for tight color specifications, potentially causing flawed pass/fail decisions and impacting product quality.

Spectrophotometers, such as the Datacolor Spectro 700/1000 product family, utilize Datacolor Tools or the ColorQuality module of Datacolor Colibri software, enabling users to view color and temperature data in real time and determine if temperature may affect readings. Source: Datacolor

Although thermochromism has long been recognized as a problem in the plastics industry, an effective way to detect its impact on color results had been lacking until recently. This created significant challenges for high-volume producers and converters. Quick and accurate results are essential in these operations because every second spent verifying specifications can increase the amount of costly waste generated by off-spec products.

Recent improvements in digital color management technologies are minimizing and even eliminating these obstacles. By accounting for the impact of temperature variations, modern hardware and software tools make it possible to obtain trustworthy measurements without time-consuming cooling strategies.

Tough Choices for Quality Control Technicians

When color matters in plastic products — and it frequently does — thermochromism can complicate quality control (QC) decisions. If a batch sample isn’t cooled to the appropriate temperature before color measurement, the readings may not accurately reflect the final, stabilized color. This can result in imprecise pass/fail decisions, ultimately affecting customer satisfaction and product integrity.

To minimize this risk, samples are often cooled to near-ambient temperatures before measurement, using methods such as extended mold dwell times, water baths or natural air cooling. Although these extra steps are effective ways to deal with thermochromism challenges, they slow the QC process. Worse, they are sometimes applied inconsistently in fast-paced production environments, introducing uncertainty into color measurement results.

Samples came from injection-molded LDPE chips measured on a Datacolor Spectro 1000 d/8° spectrophotometer under SCI, D65/10, UV inclusive conditions. Source: Datacolor

The effect of thermochromism on color is clear in these example readings. Each sample was measured at ambient and a typical “drop” temperature (that is, the temperature at which a part will retain its shape when removed from injection molding equipment).

Variations are evident in all colors tested, with reds and yellows showing the most significant shifts. Although some of the ŌłåE value differences might be considered minor, even these variations can create challenges when interpreting color measurement results.

Note: All tested colors (within normal repeatability expectations) returned to their base readings at ambient temperature.

New Alternatives in Digital Color Management Technologies

Advancements in spectrophotometer technologies and color QC software now offer solutions to address thermochromism during color testing. New spectrophotometers can sense the temperature of a sample during color measurement, providing insight into how temperature may affect color readings.

These readings can be paired with software modules, enabling technicians to view color and temperature data in real time. In addition to enhancing confidence in pass/fail results, newer software enables users to set pass/fail limits for both color and temperature, providing visual cues to indicate batch acceptability based on both criteria. This dual assessment helps ensure that the sample meets color specifications under stable, reproducible conditions, enhancing QC.

Benefits of Temperature Monitoring in Color QC

By capturing sample temperature data, manufacturers can analyze cooling process stability, detect temperature-related color shifts and identify trends over time. These insights can guide adjustments to the testing process, potentially reducing the time needed to present a sample for measurement. This approach not only improves the speed of pass/fail results but also contributes to overall throughput and production efficiency.

This technology represents a significant step forward in color QC for the plastics industry, helping manufacturers achieve consistent color quality while reducing time and material waste. By understanding and mitigating the effects of thermochromism, QC teams can ensure their products meet exacting color standards before they reach customers.

About the author: Earl W. Balthazar III, in his role as a senior applications engineer at Datacolor, is responsible for software applications for clients. He has been with the company for more than 20 years. With 40 years of experience in color matching and quality assurance, Balthazar is the subject matter expert in Datacolor’s color management software applications and custom solutions. Contact Information: 800.433.1885; ebalthazar@datacolor.com.

Related Content

Flake Sorter for Simultaneous Separation By Color, Polymer, Transparency

Tomra has introduced a new model of the Innosort Flake for sorting flakes of mixed waste plastic for recycling.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreUpdated Controller for Sealed Gravimetric Liquid Color and Additives System

NPE2024: Riverdale Global’s new RGS controller features and intuitive set-up procedure.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreRead Next

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

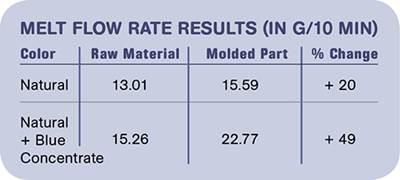

Read MoreWorking with Color Concentrates

Perhaps the greatest difficulty involving the use of color concentrates is specifying them appropriately for the material to which they are being added.

Read More