Paulson Names Karen Paulson As New President

Karen’s new post makes her the first female president of this plastics training company, a company founded by her father, and veteran educator, Donald Paulson.

Karen Paulson is the new president of Paulson Training Programs, the provider of technical training for the plastics industry. She’s taking over from out-going president Craig Paulson. Karen’s new post makes her the first female president of this plastics training company, a company founded by her father, and veteran educator, Donald Paulson.

After graduating Quinnipiac College, Summa Cum Laude, with a double major in math and computer science, Karen began her professional career in the graphics department of Paulson Training. Here, she created animations and developed the study guides for Paulson’s interactive lessons. This was the late 80s in the era before computers were used to create layouts and where each page of every study guide had to be “pasted-up” by hand. Karen has since worked in every facet of company operations, from accounting to technical support to office manager and as recently as product and content developer managing and using specialized software to build the interactive training lessons.

Karen has been responsible for the features and delivery technologies Paulson customers experience in their online lessons. And it’s her goal to continue improving Paulson’s courses by exploring the latest available technologies.

“The mission statement, in my mind, for Paulson is to serve the plastics processor by providing them with superior scientific training delivered anytime, anywhere, on any device–essentially making training convenient for individuals and their employer,” she says. “As I think about what’s important to the ´óĎó´«Ă˝, I’ll start with making sure our customers have direct, flexible access to our training and lab lessons. We just completed an update to our proprietary lab lesson platform called SkillBuilder, which integrates each interactive lesson right into the courses. Before, you had to go through the lessons and then open up another program to access the SkillBuilder lab portion.”

“Having this flexibility will make training more fluid on the plant floor. Our customers couldn’t be happier with our new improved feature,” she says.

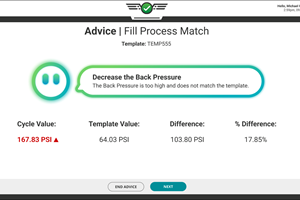

She’s also excited to launch the latest version of SimTech, Paulson’s proprietary injection molding machine simulator. SimTech was developed by her father and company founder, Donald Paulson and oldest brother AI Developer Chuck Paulson. It’s built on decades of Don’s research, data, and his thousands of scientific formulas.

“My goal with SimTech is to get this dynamic simulation tool into every molding plant to revolutionize how companies train their employees. It’s a powerful way to train for a fraction of the cost of using actual molding machines,” she says. “We will be releasing ongoing molding challenges that companies can use to compete with themselves or even better, against people from other companies. Challenges are fun and, I believe, they are one of the best ways to really learn something.”

All of the Paulson programs are based on the Paulson Method, a logical step-by-step approach that teaches processing from the “plastics point of view,” (PPV) a term coined by Donald Paulson more than 40 years ago. It builds processing knowledge by focusing on the four variables that control the molding process: heat, flow, pressure and cooling.

Related Content

Net Impact Announces Third Circular Plastic Challenge

Next generation of professionals challenged to develop a ´óĎó´«Ă˝ concept leveraging artificial intelligence in plastics value chain.

Read MoreSmart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

Read MoreAIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

Read MoreAmerican Injection Molding Institute Opens Mold Maintenance Classroom

The Beaumont subsidiary has opened the Mold Maintenance Center of Excellence classroom at its Erie, Pennsylvania, headquarters.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More