Medical Molder Expands into Full-Service Product Development

Processor Strategies: Mack Molding

In July, Mack Molding acquired Synectic Engineering, Inc., Milford, Conn., a company focused 100% on medical product development.

The trend among OE Ms of all types to push product design and development functions farther down the supply chain has forced custom molders to expand their range of skills and services. This is especially challenging to do in the medical field, which requires knowledge and capabilities well beyond the scope of plastics processing. In July, took an unusual step to fill this gap and acquired , Milford, Conn., a company focused 100% on medical product development.

Synectic Engineering employs 18, including mechanical, electrical, biomedical, materials, chemical, and quality engineers, clinicians, and industrial designers. Its facilities include 3D CAD, a model shop, in-vitro tissue lab, and Class 10,000 clean room for pilot manufacturing. The firm will remain in Milford.

Headquartered in Arlington, Vt., Mack is a $300-million plastic molding, metalworking, and contract manufacturing company with 10 locations and 1800 employees in the U.S. and Mexico. Medical is only one of its markets, but by far the largest, accounting for almost half its ´óĎó´«Ă˝. (See Nov. 2012 On-Site article.)

“We’re not just trying to get bigger—we want to get better,” says Jeff Somple, president of Mack’s Northern Operations. In his 25 years at Mack, Somple has seen a consistent problem: “There’s always a rush to get products from the drawing board to market. That means we take on products that are not fully developed, so we are doing concurrent engineering after the product launch. Now we have an opportunity to break that cycle and to eliminate the finger-pointing between those who designed a product and those who manufactured it.

“It’s so important in medical to get it right at the start. Medical development is a validative process, and you can’t change the material, the press, cycle time, process, or secondary operations after you achieve validation. Or it’s very expensive to do so.”

There’s another reason why the Synectic Engineering acquisition makes sense to Somple: “Medical OEMs want to hold fewer suppliers responsible for more. By augmenting Mack’s capabilities with engineering resources skilled in proof-of-concept, pre-clinical R&D, and product development from design to pilot manufacturing, everyone wins.” OEMs now can manage and audit only one full-service supplier, and Mack gains potential entry into a wider range of projects. That, Somple says, is much more important than any direct added revenue from Synectic’s activities.

Mack already owns Mack Prototype in Gardner, Mass., which has rapid prototyping (SLA and FDM), polyurethane molding, and CNC machining capabilities. Those go well beyond the facilities of Synectic Engineering’s model shop. In fact, Mack Prototype has done work for Synectic in the past. Mack also has an Application Development Center in Arlington, staffed with five design, development, and tooling engineers and equipped with another FDM rapid-prototyping machine. But the acquisition brings on board numerous specialized capabilities, such as a tissue lab that can test a mitral-valve repair device in a sheep’s heart or a hernia device in bovine tissue obtained from a local butcher. Or part-time consulting services of clinicians—medical doctors—who can test new devices in a hospital environment.

Says Adam Lehman, president of Synectic Engineering, “We’ll now be able to provide uninterrupted oversight and support for the full life of the program, rather than handing off to a manufacturing partner. The whole process will now be seamless, because Mack will be involved from the start.”

Related Content

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreProcess Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

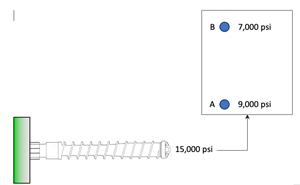

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreRead Next

Mack Puts It All Together

To be “more than a molder”—it’s an ambition held by many top plastics manufacturers.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More