Innovative Central Cooling System Adjusts Water Temperature At Each Press

A year after installing an unusual new process-cooling system, Venture Packaging molds 10% more containers on 25% fewer presses with 46% fewer workers and 50% less scrap.

When Venture Packaging decided in 1999 to build a new 48,000-sq-ft production wing onto its custom injection molding plant in Monroeville, Ohio, it used that opportunity to install central process cooling in the new extension. At the time, Venture, a unit of Berry Plastics Corp., ran 28 injection presses ranging from 160 to 550 tons. Its existing plant had three production areas with three separate cooling-water systems, all undersized in both cooling and pumping capacity and using open water reservoirs that were subject to contamination.

What Venture wanted was the efficiency of central cooling in a system that would guarantee 60 F water at the injection presses, only 3° temperature differential through the molds, and 70 psi at the mold inlet. Venture got an innovative system that cools “for free” during the winter months, air conditions the plant in summer, and has the unusual capability of cooling each press at an individually set temperature. “Until now we thought you could only do that if you installed a mold-temperature controller at each press, but our new cooling system doesn’t use heating coils,” says plant manager Howard Weatherwax.

Venture’s engineers realized, after the new cooling system went in, that cooling had been the constraining factor in many aspects of production. They learned that using colder water isn’t the only way to remove more heat and raise production. The new installation demonstrated that higher flow rates, cleaner water, and the ability to set different water temperatures at each press could multiply productivity gains.

Dial-a-temperature

Venture became the first plastics processor to install this new type of central cooling system. Designed by Engineered Process Cooling Systems (EPCS), it delivers cooling water for molds and machine hydraulics at a temperature that can be set differently for each of 16 molding presses from 550 to 825 tons. A pump at each press automatically blends the centrally chilled water supply with warmer water returning from the molds so as to maintain an operator-adjustable constant temperature at each press. Sensors and control valves maintain individual temperature control at each injection machine much more economically than if each machine had its own water heater. A central PLC monitors and controls temperatures, pressure, and flow throughout the system.

Blending chilled and warm water at the press is the big difference between the new system at Venture and previous cooling systems that EPCS had installed at other molders. The new cooling system lets operators set a specific mold temperature for each job independent of the other injection machines. “The former cooling system forced us to run all the presses at the same temperature, which meant we had to change other variables to handle the different polymers we used. Obviously, we had significant problems when we ran polyethylene and polypropylene at the same time,” Weatherwax recalls. Venture uses 13 different resins and makes over 50 different products, including cups, food containers, and lids.

The new system at Venture also delivers a larger volume of water to cool the hydraulics than was used before, and that volume is now variable, which allows individual control of oil temperature at each press. This factor alone provided immediate improvement in production rates and quality after the system was installed in late 1999.

Next, Venture began to optimize mold cooling-water temperature, machine by machine. The firm had been using 70 F water in its old plant and initially believed that 60 F water would be as cold as the new facility would ever need. But using colder water at 50-60 F and keeping a constant temperature at each mold brought even higher productivity without sacrificing quality.

Multi-loop cooling

In the new Venture plant, process heat is removed via three separate, closed water loops. They pass the energy through heat exchangers to one open water loop for the cooling tower, which has 1200 tons of cooling capacity. Only the cooling-tower water is exposed to airborne contaminants,while only the clean water in the closed loops actually passes through the molds and heat exchangers.

In open-loop systems, impurities in the water can plate out on hot surfaces of mold passages, obstructing water flow. Calcium scale and other impurities on passage walls are also thermal insulators, so they sharply reduce the heat-transfer capability of molds or heat exchangers.

Water in the closed-loop system is chemically treated to dissolve solids and keep them in suspension. An oxygen scavenger is also added to remove dissolved oxygen, so the water won’t support microbes or cause rust.

The three closed water loops are for hydraulic-system cooling, mold cooling, and air conditioning. The first closed circuit cools the press hydraulics in summer and winter. This circuit is cooled by the tower water via heat exchanger. The second closed loop uses chillers to cool the molds in summer. The chiller condenser is cooled by tower water. The mold-cooling system has three chillers but normally runs on two. The third chiller provides 220 tons of air conditioning for the new wing of the plant. This third chiller also serves as a back-up in case one of the other chillers malfunctions, when air conditioning might be curtailed or eliminated to maintain full process-cooling capacity.

The three Trane 250-ton chillers have screw compressors that can be infinitely modulated from 10% to 100% of rated capacity. Unlike more typical reciprocating-type compressors that are limited to discrete steps for capacity loading and unloading, the rotary screw compressors are infinitely variable, providing more fine-tuning capability.

Sensors track the thermal load on the cooling circuit, and the system responds automatically. Also, the screw compressors don’t have anti-cycle timers that require a 10-min delay before restarting once they have stopped. That eliminates the need for large chilled-water reservoirs that are a common site for water contamination in plastics plants.

‘Free cooling’ in winter

EPCS designed Venture’s new cooling system so that in cold weather the molds can be cooled without using the chillers. Instead, the mold water is switched to an alternate circuit with a special heat exchanger that is cooled directly by tower water. EPCS calls this “free cooling” because Mother Nature is doing most of the work. This free-cooling circuit can provide 1200 tons or 1.44 million Btu/hr of cooling during winter months. Despite an unusually mild winter in 1999-2000, free cooling saved Venture 2400 hr of mechanical chilling during the first six months after the system was installed. Venture expects free cooling to save $200,000/yr, not counting reduced maintenance from not running the chillers for half the year. Switching back and forth between chiller and free cooling is controlled automatically by temperature sensors.

Air conditioning in summer

Venture’s older plant is not air conditioned, so daytime temperatures on the plant floor could reach 120 F in summer. “We could run 55 F water through the molds in the winter, but only 65-70 F water in summer,” Weatherwax says. “Production rates could drop some 20% on hot, humid days, as we had to slow production on some presses in order to maintain dimensional stability of the food containers and lids we produce.”

Humidity was also a problem in summer, condensing on molds and corroding them. “Because it typically costs us $25,000 to repair a mold, we often had to adjust our output rate for the varying dewpoint to reduce the risk of mold corrosion,” Weatherwax notes. Because the new plant is air conditioned, Venture can now keep the new production area at about 78 F and a relative humidity of about 40-50% in summer. “Mold corrosion problems are now virtually non-existent,” Weatherwax says.

Venture’s old plant originally processed 60,000-80,000 lb/day of resin with 28 machines. Today, the old and new plants together run 150,000 lb/day with 21 presses. Venture operates three shifts, five days a week and selected machines on the weekends, with only 270 employees. Formerly, the plant employed 500 in a seven-day operation with four shifts. The reduction in workforce and hours results from both higher machine productivity, thanks to the new cooling system, and increased plant automation.

Glen Ginesi is president of Engineered Process Cooling Systems, which designs and installs process cooling water systems, and of Wilkes & Co., which designs and installs plumbing, heating, and air conditioning. Both are in Huron, Ohio (419-433-2325). Felix Theys is a co-owner of EPCS and its v.p. of engineering. He also heads his own engineering design firm, Point One Design in North Royalton, Ohio (440-230-1800).

Related Content

Industry Vet Duff Joins ACS Group

With 37 years of experience on both machinery and processor side, Michael Duff to handle aftermarket ´óĎó´«Ă˝ for auxiliary equipment manufacturer.

Read MoreIs Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

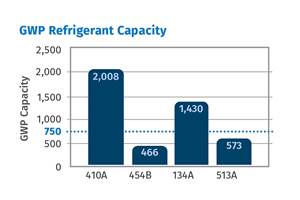

Read MoreTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More