Get Smart About Screens

Almost all extrusion processes pass melt through wire-mesh screens on the way to the die to provide filtering and improved mixing.

Almost all extrusion processes pass melt through wire-mesh screens on the way to the die to provide filtering and improved mixing. But screens also introduce process variables, raising backpressure and melt temperature and sometimes reducing output.

Screens are held by a breaker plate with holes or slots, which forms the seal between the extruder and die. Clean screens add only a small amount of pressure, maybe 50 to 100 psi, to the resistance of the head. The big pressure variable is the amount of contamination they trap.

Watch your temperature

When clogged screens are changed, pressure suddenly drops, melt temperature may do the same, and either screw rpm or line speed must be adjusted to maintain the same product dimensions. When extruding a circular product, these process changes may not cause serious problems, but in a flat or irregular profile shape, the melt-temperature change may affect the product shape. For instance, in a flat die, cooler melt will give sheet a thinner center and thicker edges. This may be compensated for by automatic or manual die adjustments, but it shouldn’t be ignored.

Placing a gear pump after the screen changer can prevent this problem by maintaining constant output through the die. But the change in melt temperature after a screen change may still require die adjustments. Also, gear pumps have very small clearances that can be damaged by hard contaminants, so fine screens are needed to shield the pump.

A few processors are “screenophobes” who don’t use screens at all. Extruders of rigid PVC, for example, know that screens make the melt hotter, which therefore needs more stabilization, which adds to material cost. Some suppliers offer special screen changers for plasticized PVC. But for rigid PVC most processors either avoid screens altogether, or use a relatively coarse pack without a changer to keep out only large contaminant particles.

Choose screens with care

Steel is the typical metal used in extruder screens. Stainless steel is more expensive but is used on some PVC lines and on others to avoid problems with rust. Nickel alloys are used in screens to avoid corrosion from fluoropolymers and PVDC.

Screen mesh, or the number of wires per inch, varies from 20 to 150 or more—20 mesh is coarse; 40 to 60 mesh is intermediate, and 80 to 150 is a fine mesh.

Most screens have a simple square mesh weave with the same number of wires in each direction. A Dutch weave has thicker wires in the horizontal direction and is specified by two numbers—for example, 32 x 120 wires/in. Dutch weave allows fine filtration without requiring multiple thin screens in a screen pack. One Dutch screen does it all.

Screens of the same mesh aren’t necessarily the same. For example, a 20-mesh screen that is made of 24-gauge wire, which is of 0.020-in. diam., has openings 0.030 in. on a side. The same 20-mesh screen made of 30-gauge wire, which has only 0.010 in. diam., has larger openings of 0.040 in. on a side. The thinner wires filter less finely and break more easily.

Traditionally, screen packs are inserted with the coarsest screen against the breaker plate and the finest screen facing the screw. For instance, the screen order from breaker plate to screw might go 20 mesh/40 mesh/60 mesh. This construction keeps screens from breaking and “blowing” contamination through the breaker-plate holes.

If the finest screen is 80 mesh or more, a coarse screen may be placed over it to keep it from being twisted from the rotating motion of the melt or torn by large contaminants (e.g., 20/100/60/20 mesh). Since this type of pack looks the same from both sides, it is sometimes made symmetrical (20/60/100/60/20 mesh) to ensure that it can’t be inserted backwards.

However, a few processors deliberately install screen packs “backwards.” Putting the coarser screen first catches the bigger particles on the upstream surface. Advocates of this approach claim that it allows more lateral melt circulation and less degradation on the upstream surface of the breaker plate.

Watch out for these

Steel screens rust in storage, so keep them away from moisture or the rust will end up in your extrudate. Worse yet, a rusty screen is more likely to break and let all the collected contamination through. Pack screens in plastic bags or rust-preventing paper.

If you are extruding PVC, don’t leave unprotected screens lying on top of the extruder. Hydrochloric acid in the air near the die will corrode them. The best practice is to run PVC with a fume hood over the die head and store spare screens far away. One PVC processor keeps his screen packs in baggies in a refrigerator, reasoning that “HCl is everywhere” in the plant.

Breaker plates can warp from being torch-cleaned too aggressively. If that happens, sealing surfaces get damaged and sliding surfaces don’t mate as well, causing leaks. Besides causing time-consuming cleanup, leaking melt may affect thermocouple readings, damage heaters, and in rare cases actually ignite and burn.

In a single-vented, two-stage extruder, the second-stage output will be reduced as build-up on the screens increases backpressure, while the first stage output remains unaffected. At around 2500 psi backpressure, melt from the first stage will start to ooze out of the vent. To avoid this, change screens at some lower target pressure. A gear pump after the screen pack will retard the occurrence of vent flow because the screw won't have to work against the die's resistance in addition to that of the screens.

Screens can suddenly “blind” if they pick up a mass of contamination, like paper, which causes a quick pressure spike in the extruder. So you must have a safety system such as a rupture disc, shear pins, and/or an alarm connected to the pressure gauge.

Allan Griff is a chemical engineer, consultant, author, and lecturer based in Bethesda, Md. He has taught extrusion seminars for 25 years and has authored several books on extrusion. He can be reached at (301) 654-1515 or by e-mail: algriff@griffex.com. His website is www.griffex.com

Related Content

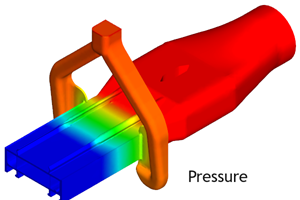

Updated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read More'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

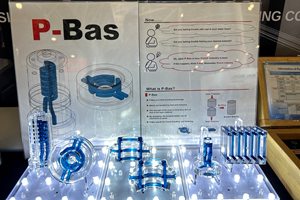

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreAuto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More