Custom Molding Slows a Bit

It’s hard to discern a definite trend in the results from our latest half-year survey of custom injection molders.

It’s hard to discern a definite trend in the results from our latest half-year survey of custom injection molders. In both 2010 and 2011, the data show molders’ ┤¾¤¾┤½├¢ stronger in the first half and weaker in the second half.

Returns from 72 custom plants at the end of 2011 showed average capacity utilization of just under 56%, down almost three points from mid-year and the lowest since the end of 2009.

The proportion of respondents who increased their utilization in the second half was only 25%, down from 52% in the first half. And 46% of molders saw lower utilization in the second half, vs.

20% in the first half. (A very similar pattern characterized 2010.)

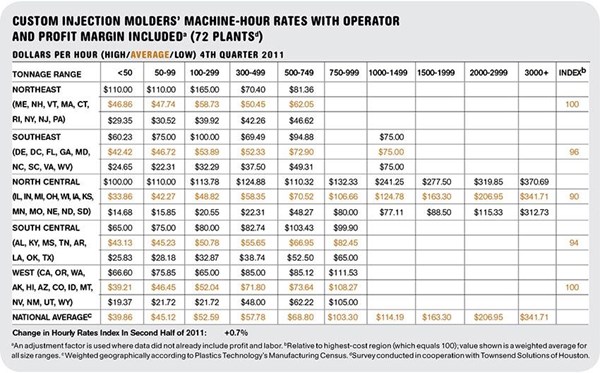

Returns from 90 molders showed no change, or a tiny decrease, in mold orders, the weakest performance since the end of 2009. And the custom molding machine-hour rate index rose only

0.7%—again, the lowest increase since the end of 2009 and about half the rate in three half-yearly surveys since then.

Molders remain optimistic, however. About 58% see improving ┤¾¤¾┤½├¢ conditions ahead, up from 49% at mid-year. However, the pessimists who see worsening conditions also rose to 32% from

17%. The ratio of optimists to pessimists was the lowest in three years.

Related Content

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.