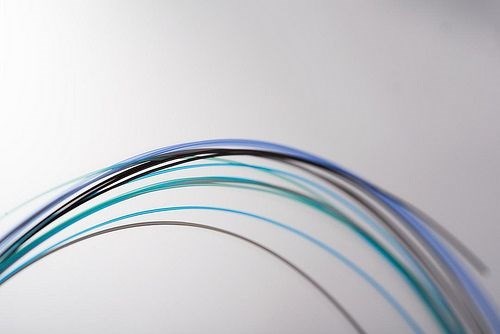

Advanced Tri-Layer Tubing for Balloon Catheters

Putnam Plastics’ proprietary extrusion process produces tri-layer tubing with improved tensile, burst and elongation properties.

To keep up with evolving requirements of medical catheters and devices, Dayville, Conn., has developed an advanced tri-layer tubing technology that boasts significantly improved tensile and burst strength, while reducing elongation. Made with a proprietary extrusion process, the company’s new Super-Tri tubing aids in the prevention of wire lock-up in catheters where guidewires are used.

According to Putnam Plastics, a leader in advanced extrusions and components for minimally invasive medical devices, the Super-Tri technology utilizes the same material combination as traditional tri-layer tubing while providing superior performance characteristics. Often used in PTCA (percutaneous transluminal coronary angioplasty) delivery systems, tri-layer tubing typically involves a HDPE inner layer for lubricity, a proprietary middle layer for bonding, and a nylon outer layer—a construction that provides a unique combination of strength, trackability and bondability.

The new tubing is said to assist in issues that have evolved from the development of higher rated burst pressure balloon catheters. Super-Tri tubing has a 98% higher burst strength and a 750% lower elongation, compared to traditional tri-layer tubing, making it very well suited for catheters that require high-pressure balloons.

The significant elongation reduction and increased tensile strength decrease the potential for guidewire lock-up, according to the company. Says Bill Appling, dir. of engineering and assembly, “For example, a PTCA inner member where tri-layer tubing is most commonly used can now be produced with a 130% improvement in ultimate tensile strength, and 170% increase in tensile strength at yield. This product provides new options in the design of catheters for the next generation of devices where strength and size are critical.” The Super-Tri tubing technology meets the same sizing, tolerances, and material configurations as traditional tri-layer tubing.

Related Content

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.