Tooling

New Software Aids Composite Processing and QC

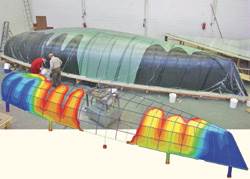

Several recent software introductions for composites design, processing, and quality control offer more sophisticated predictions of both processability and finished part properties.

Read MoreFight Hidden Corrosion in Stainless-Steel Molds

Stainless-steel tooling is used in 10% to 20% of all molding jobs and is suited expressly to harsh molding applications.

Read More3D Printers Lead Growth of Rapid Prototyping

Bringing rapid prototyping capabilities in-house is becoming a reality for many plastics manufacturers, thanks to more affordable, faster, and easy-to-use 3D printers.

Read MoreStructural Plastics: Exploring Ways to Make Molds and Parts Faster

New approaches to rapid tooling, rapid prototyping, and gas assist were highlights of the SPI Structural Plastics Conference. It also showed off several eye-opening molded parts.

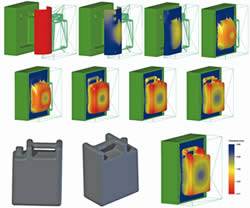

Read MoreBlow Molding Simulation: Ready for Prime Time?

Efforts have been made to simulate the extrusion blow molding process for at least a decade, but actual use has been slow to take hold.

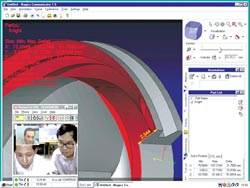

Read MoreMold Designers Put the Web to Work

The internet is redefining the tool-design process. Some mold designers are finding that using the Web to manage a tool project can shorten lead times, cut costs, and make sure vital data get to all participants in a project.

Read MoreNickel Shells Bring Shorter Lead Times And Faster Cycles to Blow Molding

Two Canadian tool builders have formed an alliance to introduce the first blow molds made by nickel-vapor depo