Xaloy LLC

375 Victoria Rd.

Austintown, OH 44515 US

330-726-4000

info@xaloy.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Xaloy LLC Supplies the Following Products

- Cylinders (Plasticating) & Liners

- Injection Molding Non-return Valves

- Screw Tips

- Screws (Plasticating)

Trade Names Offered by Xaloy LLC

- Xaloy®

- Xaloy® X-800®

Editorial, News, and Products

-

Xaloy Launches TriMetalX Barrel for Corrosive Processing Environments

Technology applies a high-performance superalloy only where needed, even on large barrels.

-

Xaloy to Reopen Virginia Manufacturing Facility

The Pulaski site was closed in 2016 by former owner Nordson, which consolidated screw and barrel operations in Ohio

-

Shopping for a Barrel? Consider the Full Cost of Ownership

Beyond just the “invoice price” of a barrel, processors should consider factors like the composition of the inlay, quality of the backing material, straightness, concentricity, machining imperfections and packaging/handling, to understand the true cost of owning a barrel.

-

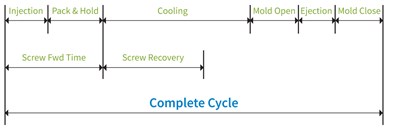

Screw-Recovery Problems Call for Special Screw Design

In injection molding, the penalty for using a general-purpose screw in an application that has special requirements often takes the form of longer cycle times. Barrier designs can help.

-

Pellet Dryer Reduces Cost of Wear From Abrasive Compounds

BKG Pellet Dryer from Nordson enabled Domo Engineering Plastics GmbH to increase productivity by cutting maintenance times up to 70%.

-

‘All-Purpose’ Screw for Injection Molding Handles a Wide Range of Polymers

A mixing section with replaceable dams is said to remedy the limitations of so-called “general-purpose” injection screws.

-

Try a ‘Complete’ Method to Clean Screws, Barrels

Pulling the screw will give you direct access to clean all surfaces. Here’s how to do so in an efficient, safe, and non-destructive way.

-

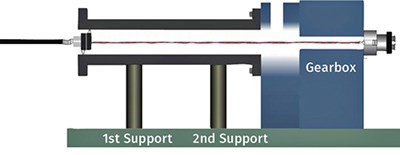

Keep Extruder Barrels Aligned…And Production on Target

A misaligned barrel causes a lot of trouble. Laser alignment is being used now to keep things on the straight and narrow.

-

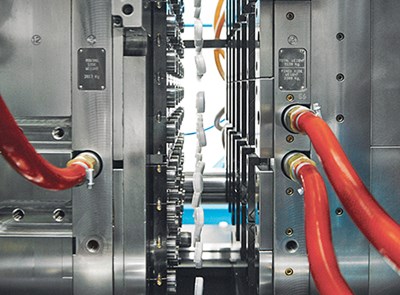

INJECTION MOLDING AT NPE: Molding Exhibits Show Off Cell Integration with Multiple Processes & Operations

If you’re interested in lightweight composites, IML, LSR, multi-shot, inmold assembly, barrier coinjection, micromolding, variotherm molding, foams, energy-saving presses, robots, hot runners, and tooling—they’re all here in force.

-

Barrel Repair: When Does It Make Sense?

Repairing a barrel can save you time and money vs. buying a brand-new one. But it’s not an easy fix and not even always possible.

-

Custom Structural Foam: A Small But Thriving Niche

How to succeed in the small but busy world of custom structural foam? Maximize your pounds per hour and use robots.

-

How to Clean Screws Nondestructively

Maintenance departments often clean screws wrongly, causing serious and expensive damage.

-

NPE News in Compounding

Compounding news at the show includes several new ways to feed low-bulk-density materials faster for higher outputs with corotating twin screws.

-

NPE News in Injection Molding

If a better machine can help your company beat challenging economic conditions, you’ll probably find it at NPE. And finding it will be easier, thanks to our editors’ efforts to sift out of some 2000 exhibits the most significant news in injection and blow molding, extrusion, compounding, and thermoforming.

-

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

-

TIME TO LEARN ABOUT Dynamic Optimization of Extruder Barrel Temperatures

Determining the optimum barrel-temperature profile is one of the most important tasks in extrusion.

-

Optimize Barrel Temperatures For Barrier Screws

Extruder operators often don’t compare the barrel-zone temperatures to the recommended processing temperature for the resin being run.

-

Induction Barrel Heating May Use Up to 70% Less Energy

Dramatic energy savings, greater reliability, and much faster response than conventional heater bands are being claimed for an alternative that will debut at next month’s K 2007 show in Dusseldorf.

-

What's New at the Show in COMPOUNDING

Compounding machinery news at the K Show next month focuses on more torque, more output, and sometimes both, for kneaders, mixers, and twin-screw extruders.

-

Extruding Biopolymers: Packaging Reaps Cost Benefit of Going 'Green'

Plastics made from renewable carbon chains, not fossil carbon from oil or gas, are suddenly a solid commercial reality. The draw isn’t just “green” marketing, but the “green” of stable prices not linked to petrochemicals.

-

NPE 2006 News Wrap-Up: Hot Shots: New Nozzles and Controls Add Sizzle to Runnerless Molding

Electrically driven valve pins, a low-cost alternative to valve-gating, mold-mounted temperature controllers, and new components for fast color changes are some of a host of new components and systems unveiled at the giant NPE 2006 show in Chicago this past June. (Some brand-new introductions since the show are also included in this report.) The news includes runnerless products aimed at everything from micromolding to shot weights up to 17.4 lb.

-

NPE 2006 News Wrap-Up: Testing and QC--New Lab Instruments Stress Affordability and Convenience

Thermal and mechanical testers, color and appearance sensors, vision inspection devices and CMMs—the NPE had them all in more compact, economical, and easy-to-use models.

-

NPE 2006 News Wrap-Up: Compounding

Much of the compounding news at the NPE Show in Chicago in June ad-dressed the growing trend among extrusion processors to become compounders.

-

What to See at NPE 2006: Extrusion

The new factor in extrusion machinery at this NPE is the influx of Asian suppliers.

-

What to See at NPE 2006: Control and Monitoring

Web-based or wireless monitoring, combined temperature and pressure sensing, cost-saving modularity, and better ways to display and report process and production data are some of the advances in control and monitoring that will be presented at this year’s NPE.One development that could have the broadest implications is Watlow’s new EZ-Zone ST modular “integrated architecture” for temperature control loops.

-

What to See at NPE 2006:Testing and QC

There’s never been a better time to outfit your lab or QC inspectors with testing and measuring instruments.

-

Take Good Care of Your Extrusion Pressure Transducers

Eight tips on installing and maintaining melt-pressure sensors in your extruder will help them last longer and give you fewer problems.

-

Rheometers: Which Type Is Right for You?