MoldTrax LLC

1555 County Road 995

Ashland, OH 44805 US

419-281-0790

sales@moldtrax.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

MoldTrax LLC Supplies the Following Products

- Data Management & Visualization

- Maintenance Management Systems

- Training & Workforce Development Services/Software

- Troubleshooting, Problem Solving Systems

Trade Names Offered by MoldTrax LLC

- MTWEB

- MoldTrax5

Editorial, News, and Products

-

Moldmakers Honored at PTXPO 2025

Several awards were presented for individual expertise as well as individual contributions to the industry and community.

-

Mold Designer, Mold Maker and Mold Repair Technician of the Year to be Named

The winners of the annual awards, including the new repair prize, will be announced at PTXPO by the Society of Plastics Engineers’ Mold Technologies Division.

-

Nominations Open for 2023 Mold Maker, Designer and Repair of Person of the Year Awards

SPE Mold Technologies Division is seeking potential nominees for its three annual awards, which will be presented at this year’s PTXPO event. Nomination deadline is Feb. 28.

-

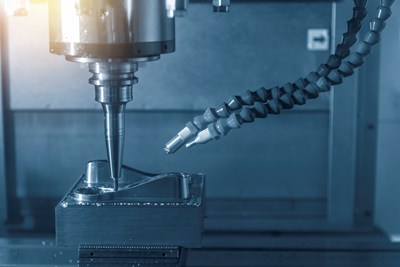

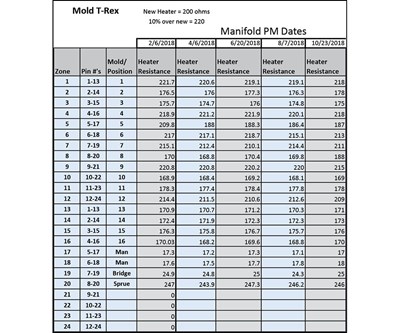

How to Detect and Prevent Hot-Runner Manifold Leaks

Minding the temperature gap at startup between the nozzle and manifold; visually and electronically monitoring signs for leaks; and preventive maintenance between runs can save you from hot-runner leak horror stories.

-

Mold Documentation Tracking System Updated

MoldTrax’s MTWEB now allows visibility in multiple locations and five languages.

-

How to Prevent Nozzle Tip Leaks, Part 1

Instead of learning from your mistakes, stop making them in the first place.

-

Time to Turn Up the Heat on Your Hot-Runner Maintenance Program

Molders are running more hot-runner manifolds than ever, a trend that’s expected to continue. But once you have them, you need to keep them in shape. Follow these tips to get going.

-

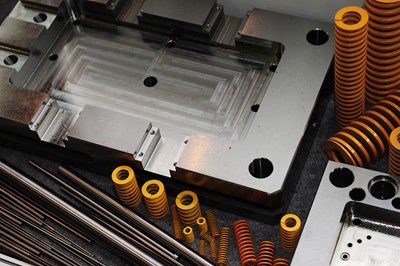

Breaking Down Hot Runner Maintenance

Improving a manifold’s maintenance plan requires specific skills and knowledge of its functioning areas.

-

Mold Performance: Tap Into the Power of Data Collection

Collecting core data in a transparent way allows molders to drill into the true cost of tooling issues and develop real goals to keep production flowing.

-

Do Scheduled PMs Really Work?

True preventive maintenance lies in accurately monitoring and counting issues and corrective actions over time.

-

More Effective Mold Maintenance: It’s All About the Data

When tooling issues are shutting down presses daily and you can’t muster the mold maintenance and operating records to figure out why, then like the song says, “Who ya gonna call?” The answer to that question proved crucial to Cosmetic Specialties International (CSI), LLC in Oxnard, Calif.

-

Tooling: Setting Up Shop: Part III

Our last column covered shop size and bench requirements for a 50 x 50 ft mold-repair shop that will have a MPP (Mold Pull Pace) of approximately 25 to 30 multi-cavity molds a week and employ four repair technicians in a six-bench layout.

-

Tooling: Setting Up a Mold Shop: Part I

I had a toolmaker once tell me he used to slam his hand in his car door before work every morning just to get him in the right frame of mind to work in his shop.

-

Tooling Know-How: Troubleshooting Defects--Part II: Hot-Runner Long Gate Vestiges

Last month, we discussed the general issues of an organized and disciplined process of troubleshooting and correcting mold defects.

-

Troubleshooting Defects: Part I

Like the three other aspects of a typical mold clean/repair job (disassembly, cleaning, and assembly) there is usually more than one way to skin the cat of troubleshooting and correcting defects.

-

The Eight Stages of Mold Repair

While the mold was still being disassembled, two “cleaners” began pulling tooling out of plates and putting them into buckets in preparation for a good scrubbing—and I mean a scrubbing.

-

What Toolroom Maintenance Supervisors Need to Know-Part II

September’s “Mold Shop” column presented an overview of a mold maintenance supervisor’s need-to-know priorities.

-

What Toolroom Maintenance Supervisors Need to Know

Those in charge of keeping molds reliable and production-ready normally start their day in the same manner—wondering what broke down since they last walked out the door—and hoping they have the resources to get it going again.

-

Why Mold-Maintenance Data Is Essential for Processing Technicians

When I was in the Navy, many different trades such as hydraulics, electrical, airframes, armament, and jet-engine mechanics worked side by side to get planes into the air, through their scheduled missions, returned to base, and turned around to do it all over again.

-

Defect Position Analysis: What It Is, Why You Need It

There are so many new technological options in mold design, moldmaking, and molding today that it boggles the mind: We can simulate melt flows to anticipate difficulties.

-

Creating a Mold-Repair Plan-Part II: The Last Shot Inspection Report

Last month, we discussed how to collect accurate mold performance data at the press through the use of an IML (injection mold layout) sheet.

-

Creating a Mold-Repair Plan-Part I: The Mold Layout Sheet

Regardless of mold type, the goal of the maintenance shop always is the same: Get a mold production-ready after it has been removed from service.

-

Cleaning Molds, Part III Ultrasonics Make Life Easier

Is there a “perfect” cleaning system for molds and tooling that would allow a significant reduction in labor hours and tooling damage while providing consistent cleaning results?

-

Cleaning Molds–Part II Blasting with Dry Ice

Today, the most popular method of cleaning plastic injection molds still remains rooted in the antiquated process of scrubbing tooling and plates by hand, one piece at a time.

-

Part Two: How Efficient Is Your Mold Maintenance?

Last month we discussed how mold performance and mold-maintenance efficiency are different things, but they work hand in hand to affect the profitability of a molding company.

-

How to Clean a Flashed Hot Manifold-Part Three

We left off last month with all 16 nozzles removed from the manifold (with the tips protected by tape) and still wired to the electric box.

-

How to Clean a Flashed Hot Manifold-Part Two

Already a familiar sight on European store shelves, the eye-catching appeal of "IML" is gaining traction among North American injection molders. The latest tooling and automation designs can handle the higher volumes needed here.

-

How to Clean a Flashed Hot Manifold-Part One

As I rounded the corner of our shop, I was confronted by a large flock of white shirts gathered around a mold on my bench.

-

Everything You Wanted to Know About Mold Maintenance

Welcome to a new column dedicated to improving efficiency in your tool room and the health and performance of your molds.