Krones, Inc.

9600 S 58th St.

PO Box 321801

Franklin, WI 53132 US

414-409-4000

sales@kronesusa.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Krones, Inc. Supplies the Following Products

- Conveying Equipment (Pneumatic & Mechanical)

- Labels & Labeling & Decorating Equipment (In-Mold, Out-of-Mold)

- Scrap Reclaim Systems

- Stretch-Blow Molding Machines

Editorial, News, and Products

-

Is There a Better Way to Heat PET Preforms for Stretch-Blow Molding?

Is near-infrared (NIR) heating better, faster and more energy efficient? So far, only two machine builders are making such claims for NIR in place of standard mid-infrared preform heating, though their systems appear to be well accepted. Meanwhile, an altogether different alternative is in the works.

-

Netstal Names New Americas’ Region President

The Swiss maker of injection molding machines has named Nadeem Amin the new president for Netstal Americas.

-

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

-

German Trial Demonstrates Recycling Technology for Multilayer Rigid Packaging

BASF, Krones, Sudpack, TOMRA collaboration achieves proof of concept for closed recycling loop for PET-based multilayer packaging.

-

New PET Stretch-Blow System Saves Energy & Downtime, Aids rPET Use

New-generation Contiform PET stretch-blow molding machine from Krones is designed for sustainability throughout.

-

Blow Molding: Something for Everyone at K Show

Packaging, industrial, continuous-extrusion, accumulator-head, injection-blow, stretch-blow, EPET, foam, sandwich co-injection—the blow molding news was wide ranging at K 2019.

-

Blow Molding: Digital Inkjet Printing onto PET Bottles

Printing directly on bottles can substitute for labels and in some cases can take place inside the blow molder.

-

Under One Roof: Innovative Recycler Closes the Loop

rPlanet Earth looks to disrupt the plastics recycling industry by creating a truly sustainable, closed-loop system for recycling and reuse of post-consumer plastics, with reclaim, sheet extrusion, thermoforming and preform making all in the same plant.

-

Simultaneous Blowing/Filling Process ‘Breaks Down Walls’ in Supply Chain

Amcor’s LiquiForm technology supports new ‘holistic’ on-site processing service.

-

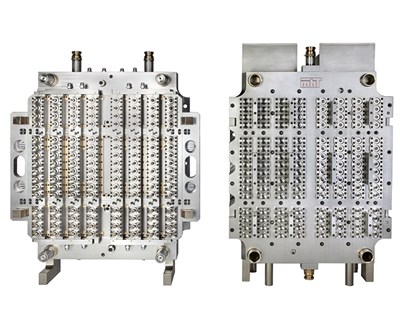

Krones Acquires MHT for PET Tooling

Krones significantly increased its capabilities in PET preform design and molding.

-

rPlanet Earth Opens Vertically Integrated Recycling Plant In California

Among a range of reclaim and polymer processing systems in place at the Vernon plant are three Welex sheet lines supplied by Graham Engineering Corp. and equipped with EDI extrusion dies and BKG melt delivery components from Nordson Corp.

-

Super-Lightweight PET Bottle For Quick Refreshment

Two new PET water bottles set benchmarks for light weight and material savings.

-

Carbonated Beverage Bottle Gets Even Lighter

Cutting soft-drink bottle weight another 30-45%.

-

Blow Molding at NPE: Pushing the Envelope in Speed, Flexibility, Energy Savings

New models of blow molding machines at the show were dominated by wheel machines and stretch-blow systems.

-

BLOW MOLDING: Electric Machines Starting to Purr

Growing use of electric drives in blow molding machinery gathered steam at the K 2010 show, as suppliers rolled out new all-electric and hybrid models for extrusion blow, injection-blow, and stretch-blow production.

-

NPE 2009 Wrap-Up: New Machinery for Blow Molding

Several new developments include a brand-new compression blow process, the first foamed PET bottles, and a preform decontamination approach for aseptically filled products sold at ambient temperature. Attendees also saw a new stack-mold Multi-Parting Line concept that doubles bottle output within the same machine footprint. (Additional NPE blow molding news appeared in May and June—see Learn More box.)

-

K 2007 Blow Molding: Electric Machines Take Hold

Development of all-electric and hybrid-electric blow molding machines may be gaining momentum, as evidenced by several new models introduced in Dusseldorf.

-

Hot-Fill Packaging: OPP and 'Panel-Less' PET Bottles Grab the Spotlight

Improved clarity and cost competitiveness, added to its inherent heat resistance, are reviving OPP’s prospects in hot-fill barrier containers. But hot-fill PET containers are raising the bar with higher productivity and ‘panel-less’ bottle designs.

-

What's New at the Show in BLOW MOLDING

There will be a strong emphasis on energy savings in blow molding machinery at K 2007.

-

K 2004 Wrap-Up on Blow Molding: Outputs Keep Rising For PET, OPP, HDPE

Among the more unusual blow molding developments at K 2004 was a closed-loop control system that monitors and corrects material distribution in PET containers as they are produced.

-

Barrier PET Bottles

No Breakthrough in Beer, But Juice & Soda Surge Ahead

-

Blow Molding - Higher Output Vies With Flexibility

The emphasis in blow molding equipment introductions at NPE 2003 is on higher output capability and greater versatility to take on emerging markets.

-

All-Electrics & Stretch-Blow Get Top Billing

Energy efficiency and production cost savings were dominant themes of the blow molding exhibits at K 2001. A handful of new all-electric machines aroused intense interest, though they are aimed primarily at niche markets. And in two-stage (reheat) PET stretch-blow molding, the focus was on boosting output per cavity.

-

Blow Molding (K 2001 Preview)

One cluster of blow molding innovations on display at K 2001 will address the need for more versatile single-stage injection stretch-blow molding (ISBM) machines. A thirst for energy savings underlies plans to launch all-electric units for PET and HDPE containers. Also in the limelight are advances in large-part technical blow molding.