FOBOHA (US)

1105 Progress Industrial Blvd.

Lawrenceville, GA 30043 US

770-362-7973

info@foboha.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

FOBOHA (US) Supplies the Following Products

- Injection Molds

Editorial, News, and Products

-

Arburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.

-

Apollo Funds to Acquire Barnes Group

Barnes, whose Molding Solutions portfolio includes Synventive, männer, Foboha, Thermoplay, Gammaflux and Priamus, is being sold for $3.6 billion to funds managed by Apollo Global Management.

-

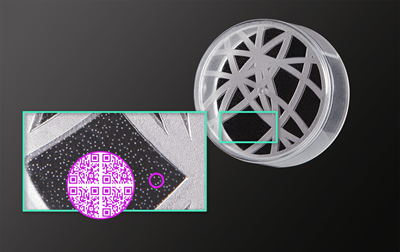

Mold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

-

Barnes Opens Customer Technology Center in Germany

Located within portfolio company Foboha’s Haslach facility, the center features an Engel injection machine, Foboha tools and leading technology from other Barnes Group 大象传媒es, including Synventive, Gammaflux and Priamus.

-

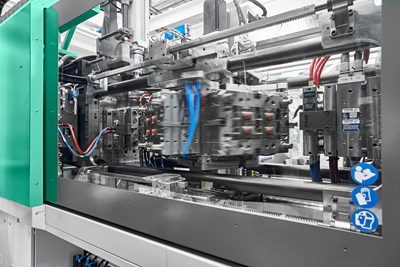

Cube Machine Portfolio Completed

Arburg’s Allrounder Cube 1800 joins previously launched machines with clamping forces of 295 and 470 tons.

-

Barnes Group Names New Head for Molding Solutions Unit

Jessica Poliner has been named president of the unit, which includes Synventive, Thermoplay, männer, FOBOHA, Priamus, and Gammaflux, replacing Norbert Scheid who retired.

-

Barnes Group Announces Restructuring

The company, whose portfolio companies include Synventive, Thermoplay, männer, Foboha, Priamus and Gammaflux, will cut approximately 400 jobs globally.

-

K 2019 Report: More Control, Faster Ordering for Molds, Hot Runners

Online monitoring of existing systems and configuration and ordering of new molds were featured at K 2019, as were numerous advances in valve-gate controls.

-

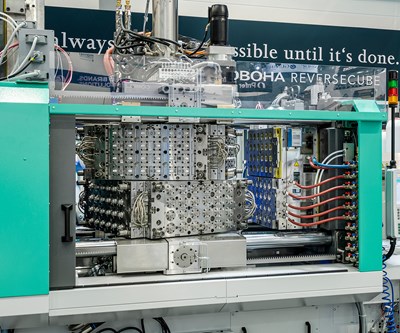

Tooling: ‘Reverse Cube’ Puts New Spin On Two-Component Molding

For two-component molding, splitting the cube mold into halves that rotate in opposite directions provides thermal isolation and long cooling times for both materials.

-

K 2019: ReverseCube Puts New Spin on Multimaterial Molding

Foboha brought a new concept to the world of cube molds, splitting top from bottom to handle different materials.

-

Tooling: Combined K 2019 Booth for Hot Runner, Molds and Process Control Brands

Barnes Group will collocate its Molding Solutions strategic 大象传媒 unit in a combined booth for the first time at K 2019, with FOBOHA, Gammaflux, männer, Priamus, Synventive and Thermoplay sharing a stand.

-

Barnes Group Acquires Robotics Firm

Private-equity group acquires Gimatic S.r.l.

-

Blow Molding: New Machines Take on Challenging Shapes

锟糉rom very small to very large, from hotel amenity bottles to automotive jounce bumpers, new and upgraded machines tackle difficult jobs while improving productivity, quality, and energy efficiency.

-

K 2016 Injection Molding: Rapid Pace of Development

Servo drives dominate. Other trends include multitouch screens, adding materials data to process controls, and Industry 4.0 connectivity.

-

K 2016 Preview: Blow Molding

Looking for speed and energy efficiency? Take your pick of new all-electric, hybrid, and servo-hydraulic machines.

-

Barnes Group Acquires FOBOHA Molds Business

Moldmaker is now a sister company of mold-sensor and hot-runner suppliers.

-

Milacron to Show Wide Range of New Technologies at K 2016 Milacron

New developments in injection and blow molding, extrusion, hot runners, and tooling will be featured.

-

INJECTION MOLDING AT NPE: Molding Exhibits Show Off Cell Integration with Multiple Processes & Operations

If you’re interested in lightweight composites, IML, LSR, multi-shot, inmold assembly, barrier coinjection, micromolding, variotherm molding, foams, energy-saving presses, robots, hot runners, and tooling—they’re all here in force.

-

Injection Molding at K 2013: Doing More with Less

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital鈥攖hese were the common themes of injection molding exhibits at October鈥檚 K 2013 show.

-

K 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

-

In-Mold Assembly: The New Frontier for Multi-Shot Molding

The drive to eliminate secondary operations is pushing multi-shot injection molding a step farther鈥攖oward assembling separate components in the tool via snap-fits, welding, and co-molding of incompatible materials.

-

NPE 2006 News Wrap-Up: Injection Molding

Advances in electric drive technology were evident in nearly every injection machine builder’s booth in Chicago.

-

What to See at NPE 2006: Injection Molding

Energy-saving all-electric machines will continue to be a big draw at NPE, where new designs or upgraded models will be found in virtually every press maker’s booth.

-

On the Cutting Edge of Multi-Shot Molding

Easley Custom Plastics (ECP) Inc. doesn't want to be just your average small to medium-sized custom molder.

-

The Next Generation of Multi-Component Molding

Multi-shot and coinjection molding techniques are staking out new territory. Mach ines are getting larger and are combining more materials or colors in more sophisticated and imaginative ways.

-

K 2004 Wrap-Up on Injection Molding: Spotlight on Electric And Multi-Component Machines

Molders were treated to a trove of injection machinery introductions geared toward applications from micro-molding to packaging to large parts.

-

In-Mold Labeling Catching on in North America

Already a familiar sight on European store shelves, the eye-catching appeal of "IML" is gaining traction among North American injection molders. The latest tooling and automation designs can handle the higher volumes needed here.