Addex Inc., USA

251 Murray St.

Newark, NY 14513 US

315-331-7700

addex@addexinc.com

CONNECT

About Addex Inc., USA

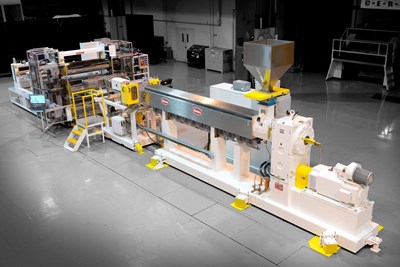

Addex, Inc is an original equipment manufacturer of high-performance components for blown film production since 1989. Addex focuses on leading-edge cooling technologies with its patented very high-output Intensive Cooling air rings, automatic gauge controls and IBC control systems.

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Addex Inc., USA Supplies the Following Products

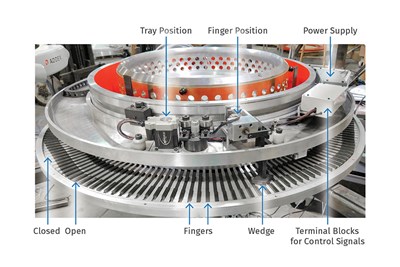

- Air Rings & Internal Bubble Cooling Units

- Closed-loop Process Control Systems

- Film, Sheet, Coated Web Thickness Measuring Equipment

Trade Names Offered by Addex Inc., USA

- IGC

- MGC

- DIBC

- MDO Lite

- EGC

- REDI

- GRAVEX

- GBR

Editorial, News, and Products

-

Novel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

-

Addex Continues to Advancing Cooling in Blown Film

NPE2024: Cooling specialist Addex debuts auto-profiling air ring for rotating dies, and new single-plenum air ring.

-

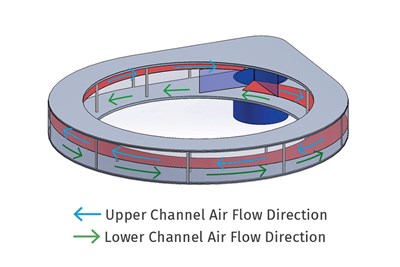

Single-Inlet Plenum Air Ring Improves Gauge Control

NPE2024: New design also eliminates multiple hoses to clean up production area.

-

Auto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

-

New Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

-

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

-

Robust, 'Smart' Bubble Cage

Addex and Pearl combine on cage that provides smooth, consistent bubble-diameter control.

-

Air Ring Add-On Brings Output to New Level

The Short Stack from Addex sits between the air ring and die and provides high-velocity air flow to boost output and lock in the bubble.

-

Film Extrusion: Towers of Power & Sustainability

At K 2019, developments in blown film highlighted recyclable film structures for new applications and technology aimed at making product changes more efficient.

-

K 2019 Preview: Green's the Theme in Extrusion & Compounding

Themes of sustainability and the Circular Economy will be visible at the booths of many suppliers of extrusion and compounding equipment—film, in particular.

-

NPE2018 New Technology Focus: Film & Extrusion Coating

Check out what’s new in blown and cast film and extrusion coating at the big plastics industry trade show.

-

Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

-

'Height-Adjustable' Twin-Stack Cooling System for Blown Film

Latest iteration of Addex’s innovative cooling system expected to boost outputs beyond 50%.

-

Air-Ring Upgrade Pumps Up the Output

Film processor Dallas Plastics boosts throughput by as much as 40% by retrofitting a new air ring—without the need for IBC.

-

Cree Charts His Own Course As President of Addex

No fly-by-nighter, Addex exec’s been flying since he was a teenager, and it’s now his preferred way to travel on 大象传媒.

-

K 2016 Extrusion: Speed, Versatility Rule the Day at K

Shorter product runs mean frequent product changeovers for processors, and suppliers responded to these trends across all extrusion technologies.

-

K 2016 Preview: Extrusion and Compounding

Regardless of what you might be extruding, the themes of speed and flexibility will loom large in extrusion at the giant show.

-

Stackable Bubble-Cooling Rings Offer Huge Output Gains

Next-generation bubble-cooling system is said to boost throughputs by as much as 60% in blown film.

-

Addex Shuts Massachusetts Location, Names New President

Headquarters moves to Newark, N.Y. for blown film specialists.

-

Air-Ring Upgrades Get Film Processor Quickly Up to Spec

PolyExpert’s trials lead to installation of three new air rings and one digital IBC control to speed changeovers and reduce scrap.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

EXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

-

Extrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

-

K 2013 Preview: Extrusion, Compounding, Recycling

Across all extrusion technologies, expect to see new standards in speed, quality, flexibility, and efficiency in both energy and material usage.

-

Extrusion & Compounding at NPE: Advances Push Efficiency Envelope

Blown film towers may have been scarce, but there was no shortage of new technology aimed at helping to make extrusion processors more profitable.

-

Extrusion & Compounding at NPE: More Output, More Flexibility, Less Energy

There won't be many blown-film lines running, but there is still much in the way of innovation going on in extrusion and compounding.

-

EXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

-

K 2010 Preview, Extrusion More…Layers, Output & Quality

In most segments of extrusion technology, the word at K 2010 is more.

-

NPE News in Extrusion

This NPE show won鈥檛 have a lot of extruders on the floor, either running or static. Instead, look for videos and announcements of new technology. You will also find lots of ingenious peripheral devices to improve output and quality and save resin. Some will do all three, and cost less into the bargain.

-

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

-

NPE 2006 News Wrap-Up: Extrusion

NPE 2006 presented a bevy of features to make film, sheet, pipe, and profile extrusion more efficient.

-

What to See at NPE 2006: Extrusion

The new factor in extrusion machinery at this NPE is the influx of Asian suppliers.

-

Capacitance Thickness Gauges: New Designs Break Old Barriers

Economical, non-nuclear capacitance gauges are opening new markets in blown film鈥攑rimarily in barrier films, where they previously suffered serious shortcomings. New gauge designs, and new ways of mounting them, make capacitance technology much more flexible.

-

MDO Films: Lots of Promise, Big Challenges

Machine-direction orientation is still discovering new market opportunities. But the technical difficulties are so great that some big projects never came of age. New equipment could make it easier.

-

K 2004 News Preview: Extrusion

At K 2004, at least a half-dozen European machine builders will show new direct-drive extruders running gearless—or nearly gearless—drives with substantially higher rpm and output rates than conventional extruders of the same size.

-

Automatic Gauge Control: Comparing the Options

Until recently, blown-film processors looking for auto-gauge control had a choice of one segmented-die system, one IBC-based system, and several segmented air rings. Now there are at least nine auto-dies, including two for high-stalk bubbles, and lots of air-ring variations. All claim to improve gauge uniformity, but there are differences.

-

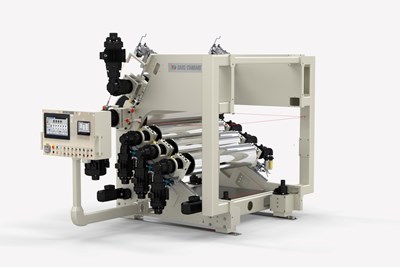

Winders: They're Pushing New Limits In Speed and Tension Control

New-generation winders for blown and cast film are winding bigger, better rolls at higher speeds and lower tension. They've gotten so fast that cast film lines can now realize their full productive potential.

-

NPE News Wrap-Up: Extrusion

Gearless extrusion, cryogenic profile calibration, wireless data communications, and automatic start-up of blown film lines are just a few of the new ways to raise efficiency and output that were highlighted at NPE.

-

Extrusion (K 2001 Preview)

Probably the most intriguing news in extrusion at K 2001 will be a novel way to extrude clear film that differs from standard blown and cast methods.