Composites Materials for FDM Printing

Materials are formulated for use on any pellet-based fused deposition modeling printer.

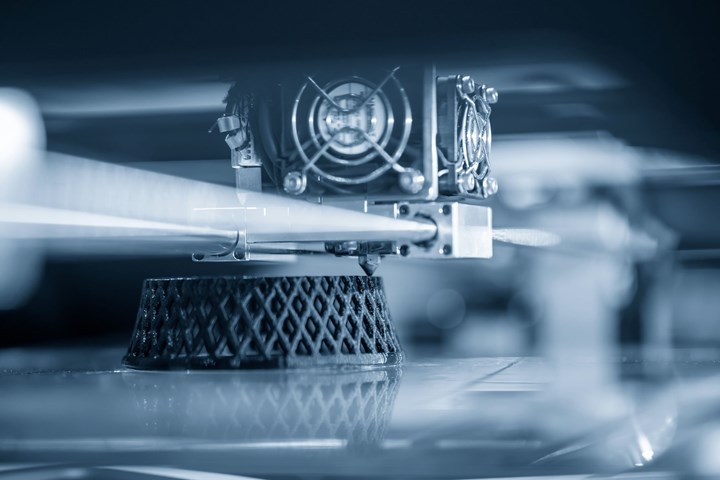

Xenia Materials announced a new range of 3D printing materials, comprised of resins combined with fibers and additives. The materials are made for use in any pellet-based fused deposition modeling (FDM) printer, for large-scale additive manufacturing (LSAM) as well as high-precision production.

Xenia will offer materials dedicated to 3D printing based on its existing range of product families: Xecarb, Xebrid, Xelight and Xegreen. The Xecarb 3DP brand includes carbon fiber-reinforced polyetherimide (PEI), ABS and PC. Xebrid 3DP includes a glass and carbon fiber-reinforced ABS. Xelight 3DP includes a lightweight polyether block amide (PEBA), and Xegreen 3DP includes carbon fiber-reinforced PA6 and PA66.

Xenia’s new line is aimed at additive manufacturing. Photo Credit: Xenia Materials

According to Xenia, the materials are recyclable and suitable for a wide range of applications and markets including industry, sport, sustainable mobility and defense.

Related Content

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.