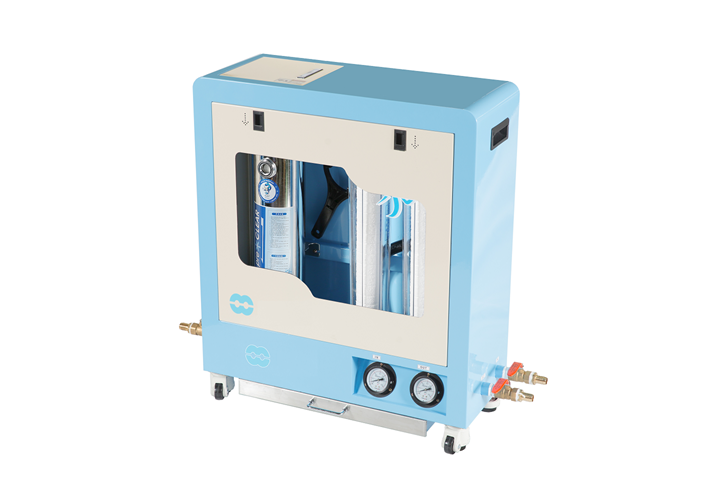

Water Quality Management System Filters, Softens Process Water

Matsui’s 3Zone Preclear system targets contaminants and water-hardening minerals to decrease molding cycle times, reduce chiller energy usage and extend mold life.

Matsui America Inc. is introducing its 3Zone Preclear system for filtering process water to help processors prolong the life and effectiveness of molds as well as chillers, TCU’s and other cooling water components. Utilizing a three-zone filtering process, the Preclear features two micro-filter zones and a proprietary third-stage ionic filter which applies an ion exchange resin. Process water is sent through a 50-µm filter, and then a 25-µm filter, before entering the ionic exchange resin filter, which is designed to eliminate water-hardening minerals calcium (Ca) and magnesium (Mg). Matsui says comparative tests have shown plant water with ppm levels of just 37 ppm in systems utilizing Preclear, compared to 540 ppm four months after cleaning in an ordinary closed loop water system.

The patented Preclear system does not require any electrical power, salt or chemicals and is easily installed between the mold and the chiller. Compact, the unit measures 32.5 by 32 by 12.5 in (825 by 805 by 315 mm). It has a maximum temperature operating range of 45 C, with a maximum operating flow range of 8 gal/min (30 l/min) and max pressure of 0.5 Mpa or less.

Utilizing a three-zone filtering process, the Preclear features two micro-filter zones and a proprietary third-stage ionic filter.

Photo Credit: Matsui America

Related Content

-

Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

-

Water Temperature Control Upgraded and Integrated into Machine Control

Engel’s new eco-flomo temperature control system continuously monitors injection mold cooling and temperature control circuits, displaying pressure, temperature and flow rate values.

-

Thermal Care Names New Regional Manager

The process-cooling technology supplier has appointed Avi Bromberg to manage equipment sales and support in the Mid鈥怉tlantic, New England, Eastern Canada and the Caribbean.