Vision System Combines 3D Laser Displacement Technology with a Smart Camera

Cognex’s new In-Sight 3D-L-4000 is said to be a breakthrough 3D vision technology, allowing factory engineers to quickly and accurately solve a wide variety of inspections.

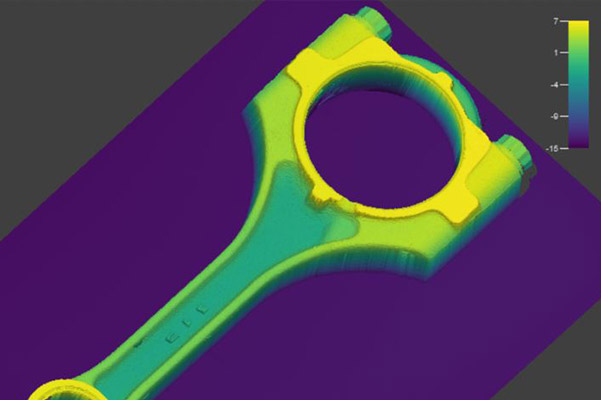

What is said to a be a breakthrough in three-dimensional (3D) vision technology has been introduced by Cognex, Natick, Mass., in the new In-Sight 3D-L-4000. This ‘unique’ vision system combines 3D laser displacement technology with a smart camera allowing factory engineers to quickly, accurately, and cost effectively solve a wide variety of inspections.

Reportedly an industry-first, the patented speckle-free blue laser optics are said to acquire higher quality 3D images than traditional laser displacement sensors, while on-board high-performance processing powers a comprehensive set of true 3D vision tools, without the need for external processing. According to the company, 3D vision tools are set up as easily as 2D vision tools thanks to the familiar and robust In-Sight spreadsheet environment.

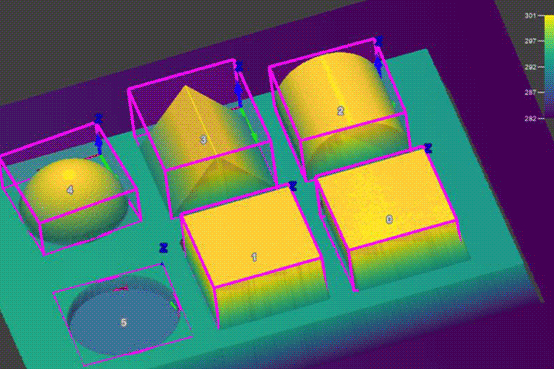

The In-Sight 3D-L4000 allows users to place vision tools directly on a true 3D image of the part, unlike typical 3D systems which transform its 3D images into a representational 2D height map for basic tool processing. True 3D inspections increase the accuracy of results and expands the types of inspections that can be performed. Moreover, because inspections are in 3D, users can immediately experience how the vision tools operate on the actual part or component.

The 3D-L4000 includes all the traditional 3D measurement tools users expect such as plane and height finding. However, it also comes with a full suite of 3D vision tools, designed from the ground up to leverage inspections in a true 3D space. Further, these vision tools were created with the simplicity of 2D in mind making them more accessible to the user.

Related Content

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.