Simulation Software Offers More Insights into Coextrusion, Layer Incapsulation

NPE2024: Compuplast to also debut simulation tools for blow molding and thermoforming.

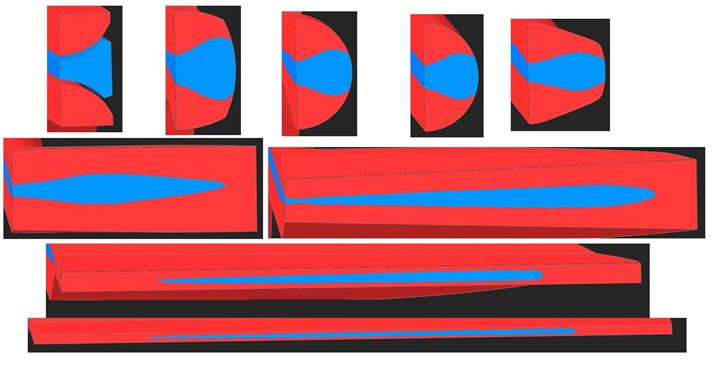

Compuplast North America is showcasing the latest releases of the Virtual Extrusion Laboratory 3D Module, which can now simulate coextrusion and show layer encapsulation. The accompanying image shows cuts in the flow field from the merge point to the die exit. Note how the middle layer deforms as it flows along and disappears in the center of the web (half symmetry analysis). Compuplast has also added the capability to predict the deformed shape of a profile in 3D.

Compuplast is also showing simulation products from . These include the fully 3D versions of its T-SIM (Thermoforming) and B-SIM (Blow Molding) simulation software. Prior versions used a “Mid-Plane” approximation of the polymer sheet or parison with 2D, triangular elements. The new 3D versions use layers of hexahedral (brick), elements to define the sheet. Compuplast is Accuform’s representative in North America.

Related Content

-

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.

-

Four Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.