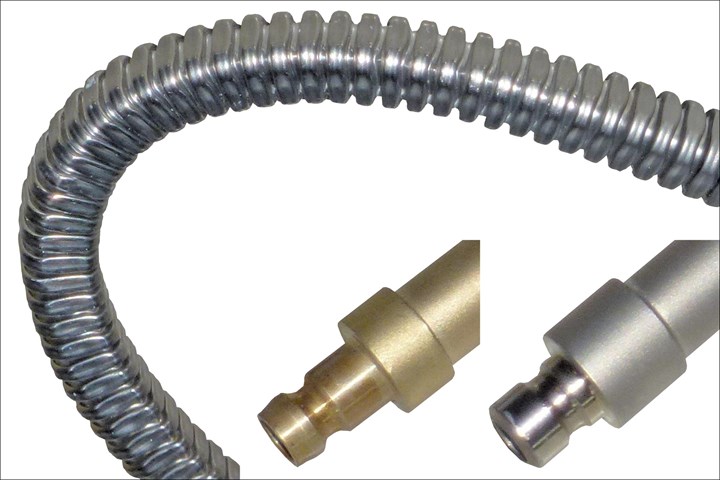

Tooling: Hose Provides Flexible Cooling

Hasco’s TempFlex Z976/ and Z977/ metal-braided hose provides assembly, interchangeability, and adaptability to any groove pattern.

Hasco says its TempFlex Z976/ and Z977/ can be outfitted on existing molds with inadequate cooling performance to provide cooling optimization, bringing temperature control to mold or spacer plates via simultaneous conformal cooling. Complex deep-hole bores and high-pressure losses due to 90° deflections can be eliminated.

The flexible metal-braided hose allows flow rates to remain the same, while high temperature resistance is also guaranteed. The square hose cross-section offers optimum heat transfer to all mold plates. Corrosion in the cooling channels can also be eliminated.

The TempFlex Z976/ is available in diameters of 9 and 13 mm with three different lengths and a metric connection. The Z977/ comes in 9-mm diameter as per the U.S. Standard. Other lengths can be supplied as custom sizes. Because there is no deep-hole boring and plugging, Hasco says using the new TempFlex for manufacturing mold plates can lead to a considerable cost reduction.

The flexible metal-braided hose allows flow rates to remain the same, while high temperature resistance is also guaranteed.

Related Content

-

Pressure Tester Checks Molds for Water Leaks

Globeius is offering the Mouldpro pressure tester for detecting water leaks within an injection mold’s cooling circuit.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its 大象传媒 — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.