Threaded Insert CAD Models Available in Online Catalog

E-Z Lok has made CAD models of its line of threaded inserts available in an online catalog.

Share

Read Next

Molded-In Threaded Inserts: The Basics

Molded-In Threaded Inserts: The Basics

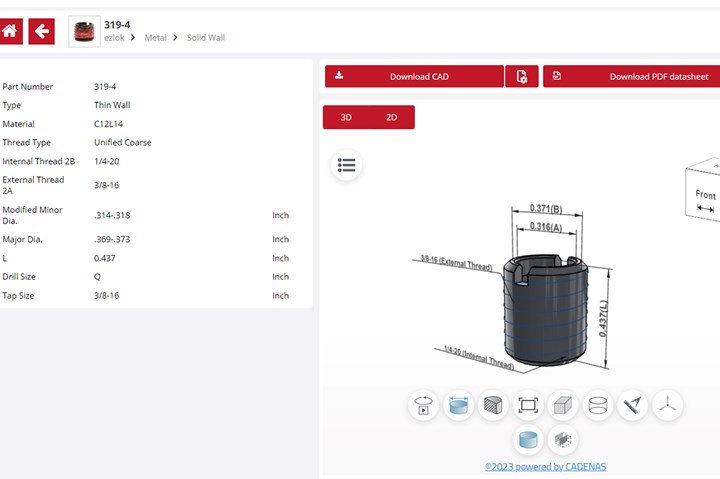

E-Z LOK, a manufacturer and distributor of threaded inserts for metal, plastic and wood, has recently launched an to showcase a selection of its products. Built by CADENAS PARTsolutions, E-Z Lok says this catalog will streamline the design and specification process for engineers, maintenance operations and OEMs by giving them on-demand access to threaded insert CAD models.

Prior to adding the 3D CAD models to its site, the company relied on its customers to create and share CAD files. In this scenario, it did offer 2D PDFs available, but no CAD files. Making CAD files valuable to engineers enables them to pull the information directly from the website and obtain product specifications early in the design phase.

The online catalog enables viewers to access product information through the E-Z Lok website, where customers can view 3D models and visualize the products as well as download PDF datasheets. Once a product is chosen, OEMs and other engineering buyers can download the CAD file in a variety of native and neutral formats.

E-Z Lok has placed a catalog of CAD model for its threaded inserts online. Photo Credit: E-Z Lok

Related Content

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.