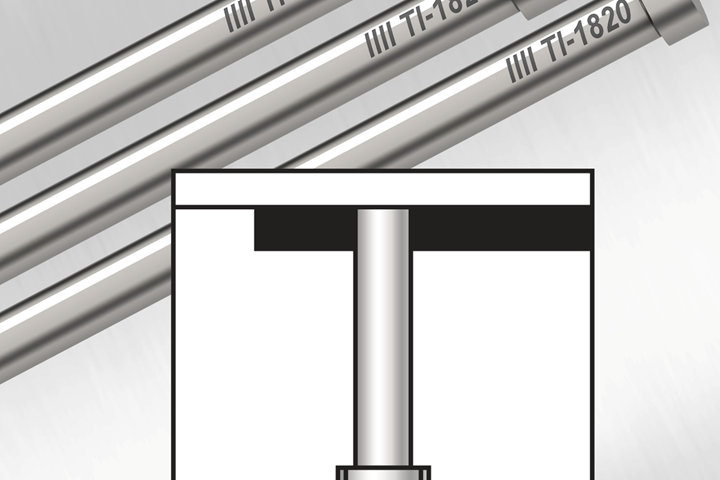

Thousandths Increment Core Pin Line Expanded

Progressive Component’s line of TI Pins now includes 267 standard sizes in new, longer lengths.

Designed to fit into small, crowded cavity and core inserts, Progressive Component’s TI Pins are manufactured with hardened M-2 steel and available in diameters from 0.060 to .320" in both 2.5 and 5.5" lengths. Progressive notes that cut-to-length and custom options beyond those are also available.

As opposed to stamping punches, which are sometimes used as core pins in molds, Progressive says its TI Pins feature heads that are precision ground to mold tolerances. Also, rather than beginning with a fractional-diameter core pin, step grinding can be eliminated with tool inserts precision cut to the molded part diameter via wire EDM. Doing so means the TI Pins only need to be cut to their finished length.

Progressive Component’s TI Pins are manufactured with hardened M-2 steel. Source: Progressive Components

Related Content

-

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.