TCU with Common Control Offers Smaller Footprint, Ease of Operation

Units sized at 3 hp and under also require 15% less floor space than earlier designs.

The new Thermolator TW-T Series temperature-control unit (TCU) from Conair is quipped with the company’s common-control and 4.3-in. color touch-screen HMI package and also includes new features that reportedly make operation and maintenance much easier than previous TCUs.

TW-T Series units sized at 3 hp and under also require 15% less floor space than earlier designs. All sizes (from 0.75 to 10 hp) have an open-back cabinet that allows for beneficial air flow around pumps and other internal components and enables visual maintenance inspection without having to remove cabinet panels.

Other new features include:

Automatic phase detection: An alarm sounds if the TCU is powered up using incorrect wiring so it is no longer necessary to look at pump shafts to determine rotation.

Dynamic maximum setpoint: Cooling-water supply pressure determines the machine’s maximum setpoint (up to 250°F standard, 300°F optional), so processors can work around plumbing limitations. Low-pressure installations can now operate readily at lower temperatures, while higher water pressure provides access to full high-end range of setpoint temperatures.

Modulating cooling valve: Ensures consistent temperature control without valve changes or deadheading, even when in different mold applications or processes, or when the TCU is moved from one machine to another.

Industrial heater construction with leak-free heater gasket: This ensures for leak-free operation in high-pressure applications. No gasket maintenance or replacement required.

Photo: Conair

The new TW-T Thermolator units are among the most recent auxiliary equipment to be equipped with the exclusive Conair common control platform – a control (and associated touchscreen HMIs) that delivers the same look, feel and user experience regardless of equipment type. Common controls simplify and accelerate the training process since people trained on one machine and control can more easily and quickly translate that experience to operate other equipment that uses an essentially identical control.

The 4-in. touch-screen user interface gives operators access to top-shelf control functions like a customizable home screen that shows two Key Process Indicators (KPI). A five-step ramp/soak program protects the process from rapid changes in setpoint and possible thermal shock as the controller tries to force the process variable to follow. An alternate-set-point feature gives users the option to use an external input—a setting on the molding machine, for instance—for added control.

With the new TCU control, calculated flow rates, or current readings from an optional integrated flow meter are always available, while trend curves of historical readings can be used to help identify potential problems before they arise. These might include mold channels that need cleaning or set-up errors like incorrect hose connections or an unopened manifold valve. Trending is also available for temperatures.

The common control platform supports both OPC-UA (the leading Industry 4.0 communications protocol, supporting the Euromap 82.1 standard), legacy control protocols, like MODBUS, as well as SPI communications (RS-485). The new TW-T controllers are also SmartServices-ready. It is easy to connect the TCUs to Conair’s unique cloud-based platform, which allows processors to connect all of their plastics processing equipment (even older or non-Conair equipment) to a single, central web-based dashboard. From here, SmartServices is able to analyze temperature-control data (or data from any other equipment) and convert it into usable, actionable information for operators, maintenance technicians, plant managers, and even procurement specialists.

Related Content

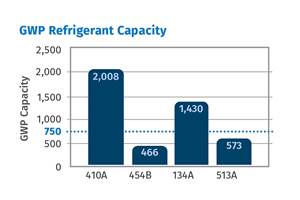

Temperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreWater Temperature Control Upgraded and Integrated into Machine Control

Engel’s new eco-flomo temperature control system continuously monitors injection mold cooling and temperature control circuits, displaying pressure, temperature and flow rate values.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreNorth American Distribution for System to Track Cooling-Circuit Temperatures, Flow Rates

Globeius is now a North American supplier of Mouldpro’s Flosense 1.0 Flexible Flow Monitoring system for tracking manifold pressures and mold temperatures.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More