Structural Foam Injection Molding Line Extended

At K 2022, Wilmington Machinery introduced the dual-injection Lumina MP1200 medium pressure molding machine.

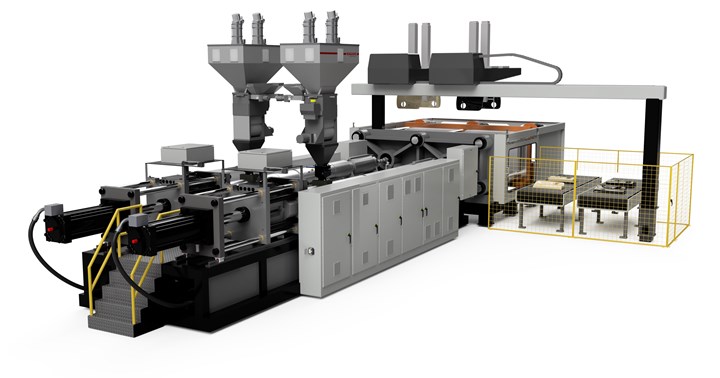

The MP1200 is Wilmington Machinery’s latest addition to its medium-pressure large-part injection molding machines first introduced at NPE 2018. The machine features dual 130-mm reciprocating and compounding injection units, utilizing the company’s in-line first-in first-out 50-lb accumulators. Able to run hot and cold runner molds, including stack tools, the machine is designed for molding large gas-assist or foam products that require superior cosmetics and high-capacity production.

For foamed products, the MP1200 features direct nitrogen or CO2 injection into the extruder barrel. Like Wilmington’s other medium- and low-pressure machines, the new Lumina is available with integrated robotics, gas-assist control, resin blending, gas generation, hot runner control and other accessories, with no licenses or fees required.

At NPE 2018, Wilmington introduced the Lumina MP800 medium-pressure machine. A hybrid with a hydraulic clamp and electric extruder drive, that machine features a two-stage injection unit capable of compounding multiple raw material components and a clamp force of 800 tons.

Wilmington Machinery’s new MP1200 is the latest edition to the Lumina line of medium-pressure large-part injection molding machines.

Photo Credit: Wilmington Machinery

Related Content

-

Exhibitor Registration Opens for K 2025

Exhibitor registration for the triennial event, which will take place Oct. 8-15, 2025, in Düsseldorf, Germany, is open with a reservation deadline of May 31, 2024.

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

Netstal To Introduce Next-Generation All-Electric Elion Injection Molding Machines at K 2025

Netstal will introduce the Elion MED in Düsseldorf with a smaller footprint and greater energy efficiency.