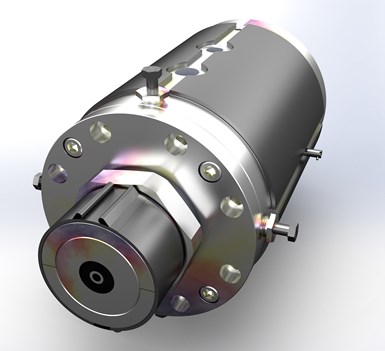

Spiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

A new Spiderless Pipe Die from Guill Tool is said to provide increased material savings compared to conventional basket dies for pipe and tubing extrusions. In the design, polymer flows through a distribution plate very similar in design to a breaker plate. Guill describes this plate as a disc into which many small flow passages are machined in a randomized pattern. This is said to distribute the polymer flow evenly around the circumference of the die body.

Photo: Guill Tool

This new die is capable of providing a finished extrusion with OD from 2 in.-15 in. It’s offered in 4140 steel, or stainless with heat treating.

Guill says material savings are realized due to precision machining, its ability to do flow analysis, and its engineering and design capabilities, among other things.

Related Content

-

This Tubing Processor Is Used to the 'Hard Stuff'

Kent Elastomer Products has emerged from its beginnings as a supplier of latex dip tubing to a leading manufacturer of high-end tight tolerance tubes for a range of applications.

-

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

-

Making Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.