“Smart Nanocomposites” for Vehicle, Wearable Electronics and Buildings

OCSiAl’s graphene nanotubes combined with a TPU to fabricate nanocomposite sheets that can harvest electrical energy from sources of waste heat.

Easy-to-process, self-supporting and flexible nonwoven nanocomposite sheets that demonstrate excellent thermoelectric properties and good mechanical robustness have been developed using graphene nanotubes from the largest global manufacturer of graphene nanotubes OCSiAl. Potetential applications include sensors for vehicles, wearable electronics and buildings. A recent paper in ACS Applied Nano Materials described how researchers combined a TPU with OCSiAl’s graphene nanotubes to fabricate a nanocomposite material capable of harvesting electrical energy from sources of waste heat.

Thanks to their high aspect ratio and specific surface area, graphene nanotubes provide TPU with electrical conductivity, making it possible to achieve high thermoelectrical performance while maintaining or improving mechanical properties. “Stiffness, strength, and tensile toughness were improved by 7, 25, and 250 times compared to buckypapers, respectively. Nanocomposite sheet shows low electrical resistivity of 7.5*10-3 Ohm×cm, high Young’s modulus of 1.8 GPa, failure strength of 80 MPa, and elongation at break of 41%,” according to Beate Krause, group leader, Leibniz-Institut für Polymerforschung Dresden e. V.

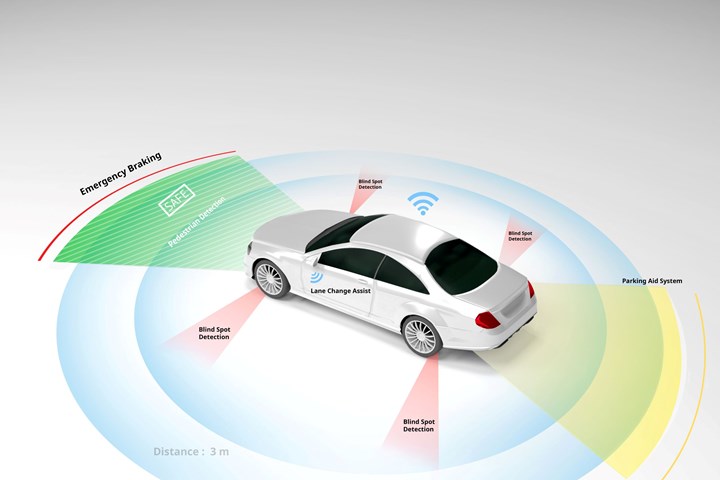

Based on expensive or corrosion-vulnerable materials which are rigid and often contain toxic elements, conventional thermoelectric generators (TEGs) currently have only low effectiveness and a relatively large size and weight. The potential to convert waste heat or solar energy into useful electrical power has emerged as an opportunity for more sustainable energy management. For example, one-third of a vehicle’s energy dissipates as waste heat in exhaust gases, and vehicles now contain more electronic devices requiring electrical energy. Similarly, lightweight wearable sensors for health and environmental monitoring are also becoming increasingly demanding. Graphene nanotubes present an opportunity to replace current TEG materials with more environmentally friendly ones. The sensors powered by such TEGs could act as a “smart skin” for vehicles and buildings, providing sensoring capabilities to monitor performance and prevent potential issues before they lead to breakdowns, ensuring optimal operational efficiency. In aircraft, no-wire nanocomposites could serve as stand-alone sensors for monitoring deicing systems, eliminating the need for an extensive network of electrical cables.

Related Content

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

-

Polymer Science for Those Who Work With Plastics: Molecular Weight — What It Is and Why It Matters

Molecular weight might seem like an abstract concept, but it plays a crucial role in determining the behavior of plastics during processing and in their final applications.

-

Advanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.