Slide Components Can Run Greaseless, Provide New Side Actions

Progressive Components says the Z-Series proprietary treatment guarantees long-term operation and durability, while there are also new side-action options for greaseless applications.

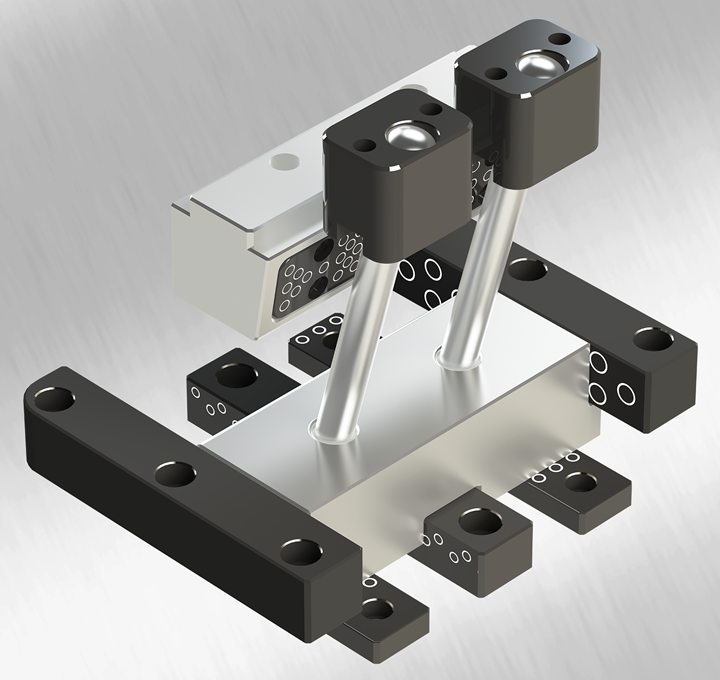

Progressive Components (Wauconda, IL) has introduced new gibs, center guides and wear strips to its Slide Component product line. Each side-action component features Progressive’s Z-Series black-nitride finish and particle-ring combination. The items are available as blanks, with pre-machined counterbores for screws, and they are designed to be cut to length for customization for each unique application.

For moldbuilders, off-the-shelf blanks can be ordered and modified in-house, or they can be delivered “Mold-Ready” from Progressive so that they’re cut-to-length with corner radii added to save shop labor and reduce lead times.

For the molder, the proprietary Z-Series treatment allows long-term operation and boosts durability, while providing new side-action options for greaseless applications.

Square gibs and center guides are available in six standard sizes, with wear strips available in eight standard, inch sizes, with a range of lengths from 6 to 13.5 in. long. CAD geometry is available from the company’s CADalog — a free parts library with downloads in multiple formats — including SolidWorks, NX, VISI, STEP, Parasolid, ACIS and IGES. Individual CAD files can be found at shop.procomps.com.

Each side-action component features Progressive’s Z-Series black-nitride finish and particle-ring combination.

Photo Credit: Progressive Components

Related Content

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

-

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.