Second-Stage Ejection Without a Second Set of Ejector Plates

Progressive Components says its Ejector Accelerators can be used when additional pin travel is required to release molded parts from lifters, stripper plates or deep core features.

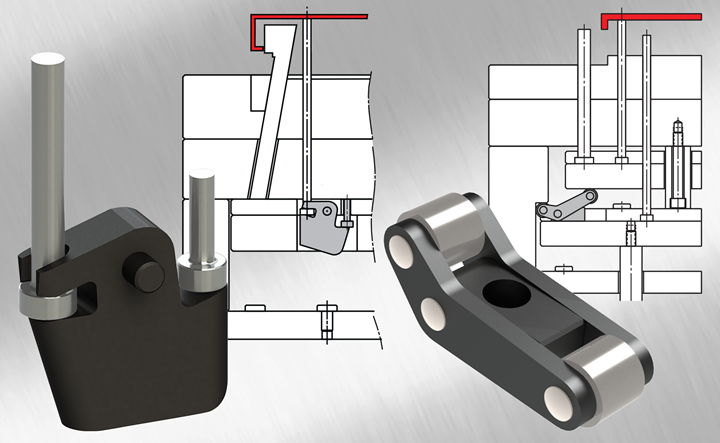

Progressive Components (Wauconda, IL) has introduced Ejector Accelerators, featuring a compact footprint that’s sized for inch ejector pins and ejector plates. The product is designed to create a second-stage ejection without the need for a second set of ejector plates. Actuating an ejector pin forward movement, the product can be used when additional pin travel is required to release a molded part from lifters, stripper plates, or deep core features.

Progressive says the Ejector Accelerator has robust strength despite a thin and compact footprint. This efficient design allows it to be situated between a mold’s other features, including lifters, support pillars and ejector pins.

Ejector Accelerators are available in four standard-inch sizes and include a kicker pin and dowel pin installed. Progressive says this product further builds out the company’s Plate Sequence Control program and is joined by a rocker-style Plate Accelerator for double ejection applications, along with additional sizes of Latch Locks for large multi-parting line tools.

CAD geometry for Progressive’s new Ejector Accelerators is available from the company’s free parts library — the CADalog — with downloads available in multiple formats, including SolidWorks, NX, VISI, STEP, Parasolid, ACIS and IGES. Individual CAD files can be found at .

Progressive Components’s Ejector Accelerator feature a compact design and can eliminate the need for a second set of ejector plates.

Photo Credit: Progressive Components

Related Content

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.