Recycling Line Boosts PET Melt Quality

At K Show and an Off Site Open House, BB Engineering demonstrated its innovations for PET recycling.

, a joint venture of and , presented a PET recycling line called Vacufil at October’s K 2022 Show in Dusseldorf.

Vacufil uses the liquid state polycondensation process for recycling PET. It combines large scale filtration and regulation of intrinsic viscosity. A key component is the patented Visco vacuum filter, which removes volatile impurities. Vacufil can be used for both post-consumer and post-industrial input materials.

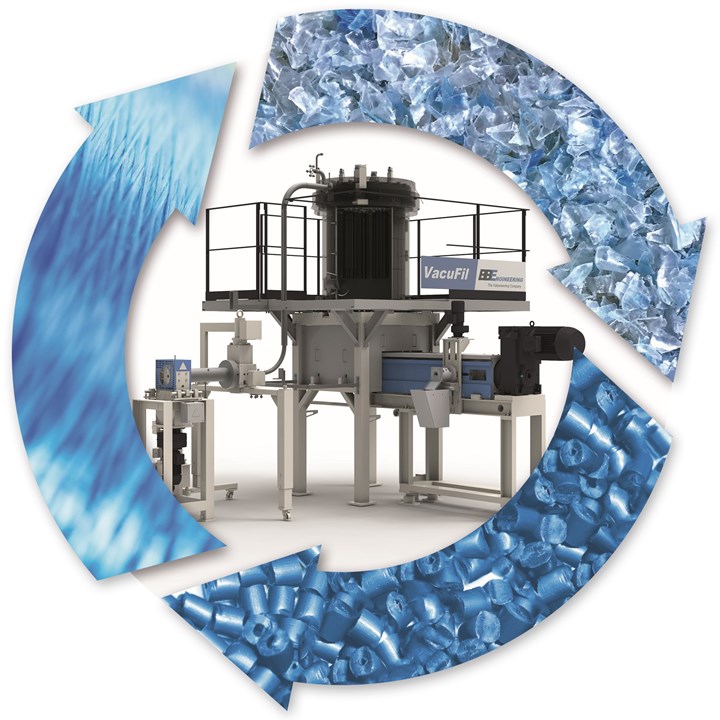

BB Engineering’s Vacufil integrated recycling plant.

Photo: BB Engineering

Vacufil is modular, and can be configured for downstream processes, including the BB Engineering’s own Variofil spinning plant. The Variofil produces a polyester yarn.

K Show attendees who went to an open house at BB Engineering during the trade fair saw this combined process in action. Its facility in Remscheid is less than 30 miles from Dusseldorf.

Related Content

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

All-Electric Injection Machines Enable More Sustainable, Energy-Efficient Processing

Stork’s all-electric injection molding machines include a breaking energy feedback system in which recovered energy can be fed back into the customer energy grid.

-

Women in Plastics Event Debuts at K 2025 Oct. 12 in Düsseldorf

The “Women in Plastics” event will debut at K 2025 on Oct. 12 at 4 p.m., where participants will have the opportunity to learn from others’ experiences and build valuable networks.