Process Cooling: Variable-Speed Packaged Chillers Save Energy

Delta T Systems ups the size range of its VS Chillers to 60 tons.

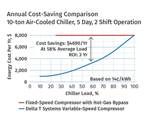

Expanding the range of its VS Chillers, Delta T Systems is now offering these units—previously available from 1 to 30 tons—in sizes of 40, 50 and 60 tons. They come standard with four variable-speed compressors that are said to operate effectively at 10% to 100% of rated capacity. According to the company, VS units provide up to 50% energy savings over chillers regulated by conventional hot-gas bypass systems (see May ’17 Close-Up for more details). The units are said to pay for themselves in less than 3 yr.

Available in air- or water-cooled versions, the units have variable-frequency drives (VFD) for soft starts and reduced compressor cycling. Other features include variable-speed condenser fans; oversized, stainless-steel, brazed-plate evaporators; one large central pump tank; individual redundant refrigeration circuits; and industry 4.0 controls design.

Related Content

-

Conair Names New Head of Customer Care

Jared Helfrich to direct the efforts of the machine builder’s growing customer care group, combining its existing parts and service and repair organization with a new range of fast-growing customer services.

-

Water Temperature Control Upgraded and Integrated into Machine Control

Engel’s new eco-flomo temperature control system continuously monitors injection mold cooling and temperature control circuits, displaying pressure, temperature and flow rate values.

-

Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.