Pelletizer Developed Specifically for Pharmaceuticals

NPE2024: Bay Plastics will also debut a new feed-roll material for strand applications.

is demonstrating a new pelletizer specifically developed for pharmaceutical applications, as well as new feed-roll material for strand pelletizing, at NPE2024 in Orlando.

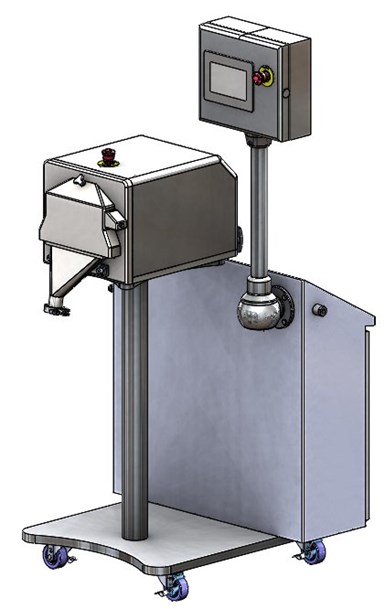

BPM’s new PH25 pelletizer features construction with 316 stainless steel at all material contact points to comply with pharmaceutical regulations. Most of the PH25’s cutting chamber parts are easily removable for cleaning and, if required, sterilized in an autoclave. The face of the machine can also be washed down.

Furthermore, the PH25 offers a wider process window and enhanced control thanks to servo motors that are standard for feed roll and rotor drive. Advanced data visibility is afforded by the machine’s HMI.

Meanwhile, BPM’s new InduraMaxx coating is a proprietary feed roll material for resin manufacturing that can handle various plastic compounds flawlessly — whether users are processing standard or filled resin, or colored material.

Featuring excellent wear properties and high heat capability (176°C/350°F), InduraMaxx is engineered with cutting-edge technology to provide optimal feed control and a uniform strand cut. Customers can choose durometer 65 Shore A and 90 Shore A to handle a range of plastic materials from soft and flexible to tough and rigid. And, for customers who need their covering quickly, BPM offers one-week turnaround time from order receipt.

Related Content

-

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

-

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

-

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.