Partnership Augments LSR Molding Simulation

SIGMA Engineering and Momentive Performance Materials announced a cooperation to optimize material data for silicone elastomers to make LSR molding simulation more reliable.

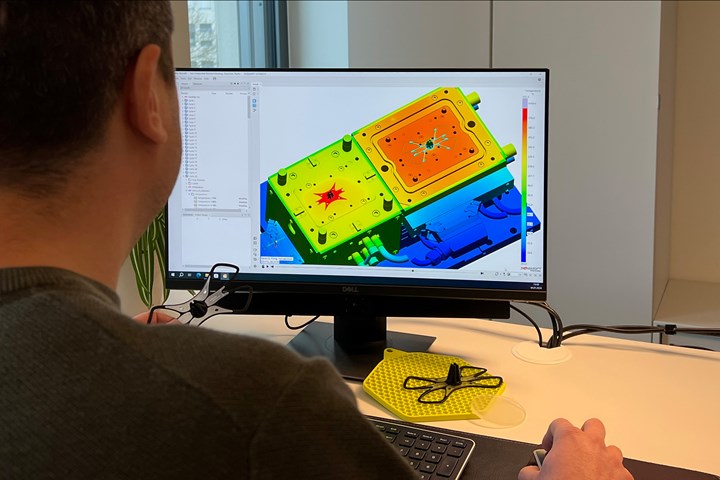

In an agreement between a provider of LSR injection molding simulation and one of the top manufacturers of silicone and silicone derivatives, SIGMA Engineering GmbH and Momentive Performance Materials are collaborating on an effort to use more precise material data to create more accurate simulation of LSR injection molding.

The companies note that the more precise the material data and understanding of the material, the better the predictions made by the simulation, adding that applying standardized laboratory values for the material properties can’t fully describe the complex behavior of components.

The companies say data from real injection molding processing is needed to refine and calibrate the material data and improve the reliability of the simulation results. Since 1998, SIGMA Engineering has offered its simulation software Sigmasoft Virtual Molding to the plastics processing sector. The program combines a part’s 3D geometry with its tooling and temperature control system, while also integrating the parameters of the production process for more accurate simulations. Sigmasoft Virtual Molding has multiple process-specific models including 3D simulation of LSR molding.

Sigmasoft Virtual Molding will apply silicone material data from Momentive to improve LSR injection molding simulation. Photo Credit: Sigmasoft

Related Content

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

-

Is There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.